Future-Proof Train Station Made with CLT

Transit Solutions of the Future

As finishing touches are put on a new Amtrak station in Tacoma, Wash., passengers can expect speedier route times and more trains on the schedule. This sleek, streamlined service is reinforced through design elements that feature Cross Laminated Timber (CLT) from SmartLam, the first commercial CLT manufacturer in the U.S.

The new Amtrak station, scheduled to open this Fall, is part of the $149.9 million Point Defiance Bypass high-speed rail project, which will reroute passenger train traffic through DuPont, Lakewood and Tacoma, creating a faster and more reliable travel route. Not only will the route relieve congestion on the present Tacoma waterfront, it will also help trim the schedule between Seattle and Portland by eight to 10 minutes and allow the addition of two more daily trains to Portland and Seattle.

The site for the station stands literally at the crossroads of old and new. The new, 10,000-square-foot station will replace an existing portion of the historic Freighthouse Square building. The station is also adjacent to Sound Transit’s Sounder station in the building and across the street from the Pierce Transit Tacoma Dome Station.

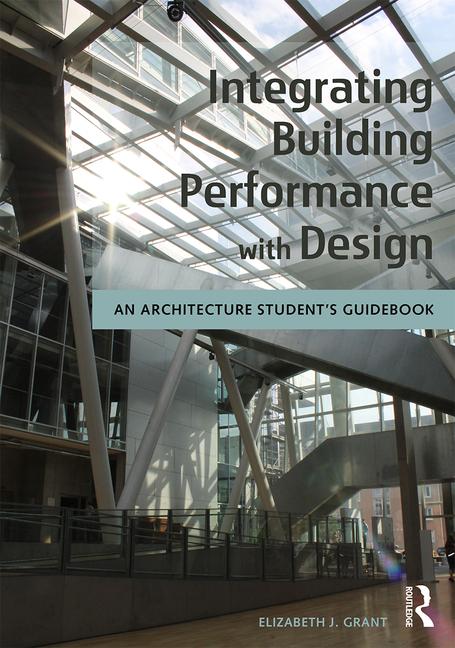

Its unique site relationships drove the station’s design: open and welcoming, with nods to the past such as wooden column and terrazzo flooring, but also sliding and vertical lift doors to create and indoor/outdoor public space and support the area’s development as a vibrant transit hub that includes retail and residential spaces. Delivering that layered message meant thoughtful selection of building materials, such as Cross Laminated Timber.

Cross Laminated Timber (CLT), is an engineered wood building system that has been used in Europe for a couple decades but not in the U.S., until recently. This engineered wood building system is made from several layers of solid lumber boards, stacked crosswise and bonded together, providing dimensional stability, strength and rigidity. CLT has proven to be an amazing alternative to traditional building materials such as steel, concrete and masonry, especially in strength, fire resistance, mold resistance, and sustainability:

Durability

With proper design and maintenance, wood infrastructures can provide long and useful service lives equivalent to other building materials. The key is careful planning and understanding of environmental loads and other external factors likely to impact a building over its lifetime.

Strength and Stability

Cross lamination provides for superior dimensional stability and offers significant shear strength performance at a very unique weight to strength ratio compared to other common structural materials. CLT panels outperform anything currently available in the U.S.

Seismic Resilience

CLT panels can create an effective lateral load resisting system. Researchers have conducted extensive seismic testing on CLT and found they perform exceptionally well with no residual deformation, particularly in multi-story applications.

Fire Resistance

A thick cross-section provides valuable and superior fire resistance for a CLT panel. Their mass means they char slowly, slowing and eventually stopping combustion. With fewer concealed spaces, fire cannot spread undetected. Compared to concrete and steel structures in a catastrophic fire event, CLT structures suffer less degradation.

Environmental

Wood is the only major building material that grows naturally and is renewable. Studies consistently show that wood outperforms steel and concrete in terms of embodied energy, air pollution and water pollution. CLT also has a lighter carbon footprint as wood products continue to store carbon absorbed by the trees while growing, and engineered wood manufacturing requires significantly less energy to produce than concrete and steel.

CLT’s unique structural properties provide increased design flexibility, allowing for distinctive and innovative projects. Due to wood's inherent ductility and unique strength to weight ratio, wood offers many advantages over the other common structural materials such as masonry, concrete, and steel. For this project, planners specified SmartLam CLT for a structural roof deck, with an exposed underside. The 20' high ceiling will be supported by exposed Douglas Fir glulam beams to help give the space a warm, inviting feeling to travelers passing through.

SmartLam's unique and warm visual aesthetic, as well as competitive pricing to other methods of construction, made this material integral to the design and construction of this station, which will be the first US rail station to include CLT in its construction. The structural characteristics support the project’s aim for a lasting link in a redefined transit system serving the Tacoma area. As a bridge between the area’s transit past and future, planners could not have selected a better material than CLT to support this new endeavor.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!