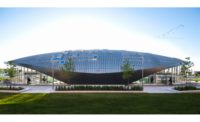

Metal wall panels fabricated by Kovach Building Enclosures with aluminum composite material supplied by Kovabond led to the successful construction of the Gila River Indian Community Multipurpose Building in Phoenix.

When an architect attempts to weave the appearance of a building into the surrounding landscape, product appearance is vital. More than 10,000 square feet of 6mm FR core material was fabricated into an exposed fastener rainscreen wall cladding system that, when installed, gave the building a basket-like appearance.

The aluminum composite material is manufactured by bonding two thin metal skins to a polyethylene core or a fire retardant core, under tension, resulting in a material that meets the toughest structural and bond tests, while remaining flat after fabrication. Still, it is flexible and light weight enough to provide designers the creative allowance not offered by other cladding materials.

“It allowed the curve of the building to be expressed in a pattern that was inspired by the traditional baskets (of the Gila River Indian community), while also providing the opportunity to dial in the color palette to embrace the vibrancy of the colors found in the cactus – the community’s namesake,” said Jeff Kershaw of the design team at Orcutt/Winslow of Phoenix. “The system allowed the panel to be mirrored on the inside, creating a screen wall that sequentially unveils the expansive view toward their sacred Yellow Peak.”

The Akimel O’odham and Tohono O’odham people of the Gila River Community were some of the world’s premier basket makers. It doesn’t take too much imagination to recognize the appearance of basket-like weaving of color in the wall panels of the Multipurpose Building. The randomness of color and the curves are very convincing. The installation was planned out beginning with the manufacturing and packaging of panels.

“We don’t get too many chances to install a serpentine radius wall like this,” said Kyle Kovach, project manager for Kovach Building Enclosures of Chandler, Ariz. “We like shining when we get a chance.”

Kovach said organization in the manufacturing plant was integral to the success of the installation. The design called for a random pattern of colors—Palm Frawn, Lazy Lizard, Regal White and Medium Bronze. Each column contained 26 panels, measuring 12 feet wide by one foot high. (Some columns contained windows so the number of panels was less.) Each panel was pre-punched during fabrication on a CNC machine to account for 12 fasteners, all custom-colored by SFS intec to match the panel color it would be fastening.

Some cladding manufacturers offer a limited number of colors and charge extra for custom colors. The product does not charge more for custom colors, offering architects complete design freedom and a better chance to stay within their budget. The sheets are offered in a variety of widths allowing customers to maximize material usage, creating much less waste and saving money.

Because each column radius varies slightly, Kovach Building Enclosures had to account for the correct number of panels in the colors required to provide a specific, but “random looking” layout. When a column of 26 panels was fabricated, they were packaged in the opposite direction in which they were to be installed. The Kovach crews could take panels off the top of the stack and install them in the order they were packaged, making sure to use matching fasteners.

Installers prefer working with material fabricated in-house, in a controlled environment. Factory-fabricated systems have the advantages of speed, quality control and packaging coordination, all which create lower field labor costs as compared to field-fabricated systems.

“I can’t emphasize enough how important the fabrication and then the packaging at the manufacturing plant was to the ease of installation,” Kovach said. “Preparation like this is easier to handle in a controlled environment. It makes the install a lot easier.”

The panels are easily curved, allowing the designer the freedom to incorporate architectural elements—like concave and convex curving—not possible with other cladding materials.

“The Kovabond product is easy to work with,” Kovach said. “It’s easy to fabricate, it’s a more universal product. The composite material itself looks a lot better than standard single-skin panels; it’s flatter. And you can make bigger panels with it than you can with single skins because it’s available in sizes that vary from standard coil.”

Kershaw was very happy with the end result. “Working with Kovabond throughout the design process, we were able to maintain the design intent of the building and find creative solutions for staying within budget in an effort to give this community a building that was rooted in their identity,” he said.