How Do Moisture Surveys Transform Roofing Forensics?

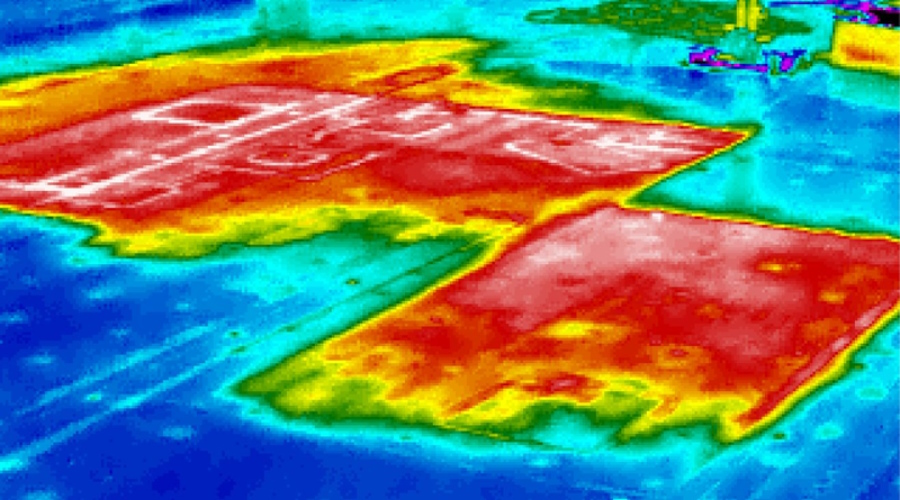

Infrared Image (heat picture) of Moisture Damaged Roofing. Image courtesy of IR Analyzers

Roofing forensics is an essential accountability process for commercial builders and construction workers. Thorough examinations solidify safety, compliance and sustainability. Recent advancements in thermal imaging will take roof inspection tools to the next level. What is a forensic roof inspection, and how does it combine with thermal technology to make structures secure?

What Is a Forensic Roof Inspection and Thermal Imaging?

A forensic roof inspection is a process validating roofing quality and installation. The procedure must inspect the assembly’s quality and prove it can perform to expectation. Experts seek all deficiencies, including cracks or leaks severe weather would compromise. Sample retrieval is vital to check for harmful substances, like asbestos or mold.

Commercial building renters and owners hire these professionals as a third-party assurance. Many want or need validation for stakeholders that the builders performed their duties accordingly. They may require verification for regulatory adherence.

How does this relate to thermal imaging? Advancements in roofing forensics leverage thermal images to quickly identify problem areas in a roof. The imaging reveals temperature variances in the structure using infrared thermography in special cameras. Some utilize drones to carry out thermal imaging, letting workers do ground or aerial inspections. Ideally, the roof should be mostly the same color.

Technology upgrades productivity by swiftly identifying concerns. It is much faster than conventional methods. Walking the roof’s surface and looking for softness and compromises is more labor- and time-intensive. The imaging results immediately determine where to prioritize investigations and issue repairs. Once recognized, inspectors forge a remediation action plan.

The beauty of these roof inspection tools is their accurate and noninvasive nature. Thermal anomalies are apparent and easy to track. The cameras do not need to penetrate the roof’s surface, and workers do not remove or overhaul vast sections. Commercial outfits hiring thermal imaging rooftop inspections enjoy a damage-free audit to keep the infrastructure as untarnished as possible. How does its incorporation improve upon existing forensics methods?

Detecting Moisture Intrusion

Pooled moisture lights up thermal imaging during a forensic roof inspection. It is usually due to a leak or inadequate sealing, although HVAC is another probable cause. The camera picks up on several things. A roof does not produce heat independently, but the properties of collected water change based on the outside temperature. In cold weather, inspectors notice the thermal conductivity of moisture intrusions.

Another material defect is delamination, or any peeling in roofing revealing temperature or heat transfer differences. A thermal bridge is one way this manifests. The shortcomings worsen during heavy rains and winds, such as hurricanes.

Experts see a prominent area where heat is moving and can diagnose missing insulation or moisture intrusion causing energy loss. The method permits targeted repairs and early communication with additional professionals, such as mold experts.

Diagnosing Insulation Defects

The imaging’s accuracy relies on insulation and roof membrane performance. Experts must read results based on insulation materials and installation style, influencing how thermal images appear.

Their readings allow them to recommend commercial buildings with the most appropriate insulation for their structure’s environmental control needs. Thermal imaging helps more than roof quality — it bolsters indoor comfort and minimizes heat loss.

Absorbency is the primary trait forensic specialists watch out for. For example, imaging highlights the presence of styrene versus fiberglass insulation based on thermal patterns without tearing out the roof. The information enhances roofing forensics because freer water dispersal hints at absorbent insulation, whereas more stark designs mark less absorbent materials.

Improving Safety

Disruptive forensic examinations put investigators in danger and set a poor precedent for best practices. Remote roof inspection tools let analysts keep their feet on the ground when obtaining data. They do not have to traverse potentially insecure roofs. Thermal imaging is perfect for companies wanting to lower incidents and injuries caused by unsafe working environments.

Thermal imaging keeps organizations compliant. Additionally, fewer claims mean reduced communications with insurance companies. It saves money and morale as workers feel more empowered on the job.

Identifying Material Deficiencies to Make Green Roofs

Thermal imaging reveals insulation defects alongside roofing material worries. Commercial builders long to know these details, mainly if repairs are inside the warranty. Alongside delamination, cameras may show:

- Cracks and leaks

- Manufacturing defects

- Adhesive inefficiencies

- Blistering

- Shrinkage

Identifying these issues from thermal images is crucial for making roofing more sustainable. Errors lead to decreased energy efficiency and increased safety oversights for occupants. For example, commercial contractors attempting to meet environmental, social and governance goals for sustainability benchmarks must alert building managers how the roofing liabilities harm their power consumption and carbon footprints.

Studies have explored how thermal imaging was essential for testing waterproofing for green roofs in Egypt, making expenses more reasonable and problem control faster. Thermal images notate concerns with greater specificity than other methods. Pointed repairs will save on HVAC, electricity and water.

Predictive Maintenance Leads to Cost Savings

Conventional forensic roofing inspections may not include thermal imaging. Other methods may be less comprehensive and effective in finding every issue. Cameras and drones are ideal for detecting predictive maintenance opportunities, even if they are not prominent concerns at the point of inspection. Imaging prevents problems from escalating.

Thermal gradients are red flags, yet they direct upgrades, repairs and retrofits in a productive direction. Massive structural concerns transform from reactive to proactive because of thermal imaging. The roof’s and insulation’s life spans compound dramatically because improvements are gradual instead of requiring complete rework.

Better B2B relationships are an added benefit. Commercial building managers become more trusting of construction and roofing professionals, supporting each other with regular patronage. Each party emphasizes the roof’s health in the long term instead of only responding to potential emergencies. It forces the industrial mindset to shift. Predictive maintenance is cost-effective compared to waiting for intense infrastructure damage to appear out of nowhere.

The Next Generation of Roofing Forensics

Thermal imaging is transformative for construction and building workers in commercial units. Teams must leverage as many roof inspection tools as possible to increase safety for high volumes of occupants. Thermal imaging is a nondestructive way to execute audits identifying concerns before damage occurs.

Financial, labor and material resource savings are available for agencies worldwide employing these revolutionary techniques. It is necessary to set new precedents for the future of roofing inspections.