What Roofers Need to Know About Working Around Lightning Protection Systems

Roofers deal with new challenges on every job. Installing a watertight roofing system requires attention to every detail from exhaust penetrations and skylights to snow retention and gutters.

No matter how good you are at providing your customers with a watertight roofing – or re-roofing – system, installing, connecting and/or disconnecting a lightning protection system is a task better left to specialists.

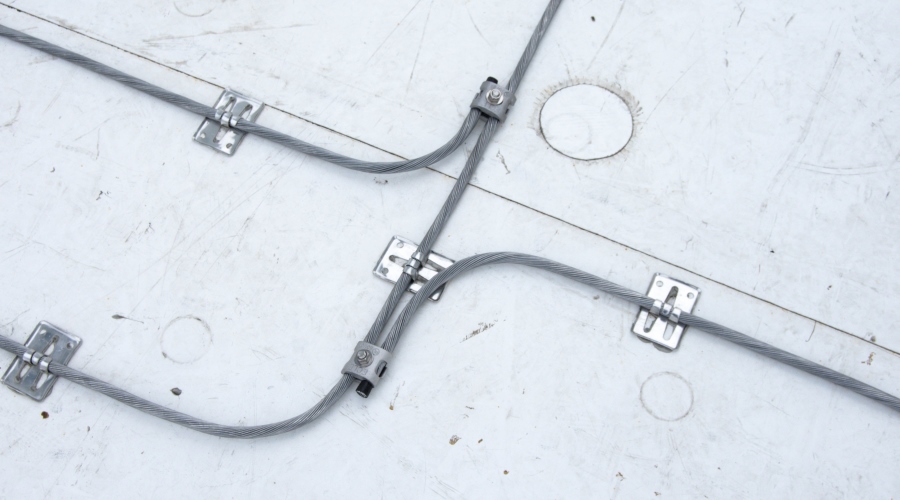

The greater part of any lightning protection system is actually installed below roof level, requiring plenty of cooperation and communication between those installing the roof, those installing rooftop equipment and the lightning protection systems contractor. Various components of lightning protection systems are installed before, during and after the roof installation, meaning everyone should be included in the project schedule. Lightning protection system installers are often times one of the first and last trades on the jobsite.

As with all other aspects of erecting a building there are guidelines and standards that must be followed. Installing a lightning protection system is no different. The National Fire Protection Association (NFPA) publishes a document governing lightning protection systems: NFPA 780, which is more than 100 pages. It provides lightning protection system installation requirements to safeguard people and property from the risk of fire and related hazards associated with lightning strikes and has specific requirements for the placement of fasteners, air terminals, conductors and grounding systems.

Those who install metal roofing will be familiar – or should be familiar – with problems caused by the use of dissimilar metals. It’s important to know what metal materials you’re working with to prevent galvanic corrosion. This is especially true for lightning protection systems, which utilize components constructed from either copper, aluminum or some combination of both metals. When dissimilar metals come into contact with electrolytes, including condensation, rainwater or other sources such as oil, dirt and airborne particles, it can produce an electrochemical reaction, leading to the corrosion of one or more metals. This can produce staining or even degrade the integrity of the metal itself.

The Lightning Protection Institute (LPI) promotes lightning protection education, awareness and safety, including certifying the installation of lightning protection systems. Underwriters Laboratories (UL) oversees product testing for lightning protection material components in the factory prior to shipment for listing and labeling. UL Standard 96 addresses the minimum requirements for construction of air terminals, cable conductors, fittings, connectors and fasteners used in lightning protection systems.

UL visits the East Coast Lighting Equipment manufacturing facility and other production plants quarterly to verify continued compliance.

Since lightning protection systems fall outside the scope of what is typically inspected by local officials, it is common for project specifications to call for a third-party field inspection and certification of the lightning protection system. These field inspections of completed installations can be arranged by the Lightning Protection Institute – Inspection Program (LPI-IP) through certified installing contractors.

Needless to say, requirements and standards are stringent and necessitate a specific knowledge to install, uninstall or work around a lightning protection system if you want the system to meet standards. Anyone working on the roof also must be sure not to inadvertently disconnect the lightning protection system, possibly rendering the system nonfunctional or voiding the third-party inspection.