In Pursuit of Environmentally-Friendly Concrete

Concrete is a complicated building material. It is a composite of sand, gravel, cement and other constituent components that are never quite the same, nor sourced from the same places, nor mixed and delivered the same way. Moreover, we use an enormous amount of concrete. It is difficult to fathom how much concrete we use. According to Vince Beiser, author of The World in a Grain, across the globe we are adding the equivalent of eight New York Cities to the world every single year.

At such a scale it is no wonder that creating concrete adds large amounts of carbon dioxide (CO2) to the atmosphere. The mining and transportation of sand and gravel requires energy-intensive processes. However, it is what binds the sand and gravel together—cement—that is the greatest contributor to greenhouse gas emissions. According to a recent study, the chemical and thermal combustion processes involved in the production of more than 4 billion tons of cement globally each year accounts for around eight percent of global CO2 emissions.

In order to realize a more sustainable built environment, we must address concrete: how we use it; how it is made; how much of it we use. There are a number of alternatives to structural cast-in-place concrete; but in this era of unprecedented global urbanization our building design and construction industry is not likely to move away from reinforced concrete structures any time soon. Ceding this notion, what can we do to improve concrete today? On a recent multi-story commercial office project in Indianapolis, I was prompted to explore our concrete mixes and look for opportunities to lessen the environmental impact of the building's structure.

Mix Designs

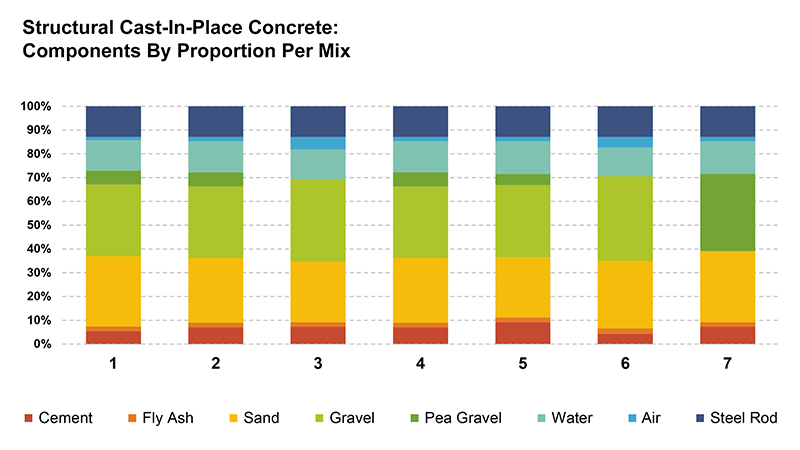

The following is a summary of the mix designs for seven different lean structural cast-in-place concrete mixes used for the Indianapolis-based commercial case study. Table 1 and Figure 1 breakout the basic constituent components of these non-air-entrained mixes. All of the concrete was reinforced with steel rod (assume to comprise an average of 4 cubic feet for every 31 cubic feet of steel reinforced concrete in the structure).

|

|

|

Table 1: Structural cast-in-place concrete mix design summaries for the Indianapolis case study. Table courtesy of Daniel Overbey. |

|

|

|

Figure 1: Graphic representation of the structural cast-in-place concrete mix components by proportion per mix for the Indianapolis case study. Figure courtesy of Daniel Overbey. |

Collectively, this is a "20% fly ash" mix. Could we have added more?

For most structural concrete mixes, the "50/30/20" rule-of-thumb is a good starting point:

- At least 50 percent of the cement (by volume) is retained.

- Up to 30 percent of the cement is supplanted by slag.

- Up to 20 percent of the cement is supplanted by fly ash.

For the lean concrete mixes examined here, the averages of the components were as depicted in Figure 2.

At 2.0 percent, the fly ash actually constitutes right at 22.7 percent of what would otherwise be the total cement. Could the concrete provider have added more fly ash or slag to the mixes? Probably, but it may have come at the expense of performance:

- As more fly ash or slag is added, the set time increases. At 50 percent slag/fly ash, the 28-day strength may require twice as much time (56-days). This could be a major impediment on the schedule.

- Slag has been documented as leaving an undesired visual impression on the concrete.

|

|

|

Figure 2: Treemap of the average volumetric proportion of each mix component for all of the structural concrete used in the Indianapolis case study. Figure courtesy of Daniel Overbey. |

Limited Opportunities for Recycled Content or Material Reuse

Concrete is necessarily local because hauling sand, gravel, cement, or water is intensive. A cubic yard of typical reinforced concrete can be between 3,800-4,000 lbs.

An inventory of the lean concrete mixes used in this Indianapolis case study is offered in Figure 3. There were two important issues regarding the proximity of the concrete materials:

- In LEED v4/v4.1, close proximity to a job site is a secondary attribute. Under LEED v4, products sourced (extracted, manufactured, and purchased) within 100 miles of the project site are valued at 200 percent of their base contributing cost regarding leadership extraction practices (e.g., recycled content, reused materials, etc.).

- The marketplace is fluid and quarries and other sources for fly ash, slag, and reinforcing steel can be difficult to predict.

|

|

|

Figure 3: The proximity of each mix component's extraction / processing source to the Indianapolis case study job site. The 100-mile radius is exhibited for reference. Please note that the cited distances are approximate and based on travel distance. Figure courtesy of Daniel Overbey. |

Fly Ash Sourcing

Consider fly ash in our case study. Fly ash is a byproduct from burning pulverized coal in electric power generating plants. During combustion, mineral impurities in the coal (clay, feldspar, quartz, and shale) fuse in suspension and float out of the combustion chamber with the exhaust gases.

Almost 3/4 of Indiana's electricity generation is coal-based. Slam dunk, right?

Not so fast. Our local concrete providers cited concerns with Indiana-based fly ash sources in terms of long-term available quantities and/or consistent quality. Moreover, EPA regulations are having an impact on sourcing opportunities. As a result, concrete providers may have to reach farther to identify a stable source that they can continue to use. In our case study, the fly ash came from the Rush Island Power Station in Festus, Missouri—282 miles from the job site. It was transported by truck.

In other words, the our only "recycled" material (besides the reinforcing steel) in our concrete mixes is the one material outside of the LEED 100 mile radius.

Slag Sourcing

Slag seemed like a great alternative. The National Slag Association indicates over a dozen active slag sources in Indiana. Concrete provider I spoke with cited consistent slag resources around Chicago.

Time-of-year can exacerbate set times. Slag performs best in hot ambient temperatures and placements in larger volumes because it does a great job at lowering the heat of hydration of a mix. Since slag is not as widely used as fly ash, it is not as readily available but often can be conveniently sourced with enough notice and volume. Concrete providers frequently use slag in U.S. Department of Transportation (DOT) applications such as bridge structures and barrier walls. The concrete providers attested that slag is becoming increasingly popular in LEED applications.

The value proposition of using slag may have shifted as well. Slag used to be desired because it helped reduce cost; but in recent years it has become similar to—and in some cases more expensive than—cement. Therefore, in a competitive bidding environment higher substitution rates are not utilized as much unless they are required.

Can we recycle concrete aggregate?

In pursuit of other recycled content sources, could the aggregate from local concrete be reconstituted in new concrete pours? For some non-structural applications, reused aggregate or other inert items (e.g., tumbled glass chips) may be acceptable. However for structural concrete, the grinding and mixing up of old and new aggregate creates an unacceptably less predictable concrete strength. The reconstituted aggregate could potentially weaken the concrete.

What about injected CO2?

A recent innovative advancement in concrete is to captured CO2 and injects it into concrete as it is being mixed. The benefits of injected CO2 processes are threefold:

- Reduced cement use: By allowing concrete mixes to utilize less cement, the embodied environmental impacts associated with cement are reduced.

- Sequestered carbon: The CO2 injection process in effect helps concrete serve as a carbon sink.

- Increased strength: Recent data suggests that injected CO2 could increase concrete strength by 10-20 percent.

An injected CO2 process was utilized in the Indianapolis case study to reduce the total cement use by 6.4 percent. However, the life-cycle assessment model indicated that the total amount of carbon associated with the structural concrete (14,660,918 kgCO2 eq) was only reduced by 1.7 percent. Helpful, but not nearly a silver bullet to achieve the LEED v4.1 thresholds.

In Conclusion

The building design and construction industry is becoming more advanced with regard to methodologies and technologies to reduce the enormous life-cycle environmental impact of concrete use throughout the world. Until we develop a truly regenerative alternative to the concrete used in our buildings, we must continue to advance solutions that reduce the negative impacts of concrete. However, those solutions present a constantly moving target, prompting project teams to be ever diligent in their designs, specifications, and construction methods.