The Importance of Low-VOC Insulation

Creating Healthier Workplaces with Smarter Insulation Choices

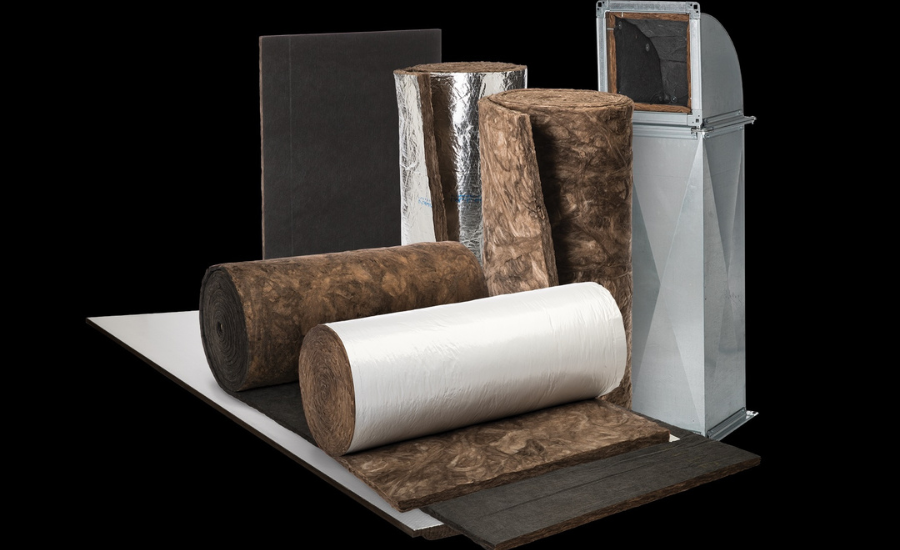

Knauf EcoBatt Insulation Installation. All photos courtesy of Knauf Insulation, Inc.

Every choice made in building design, construction, and maintenance contributes to the environment we live in, directly impacting our health. This environment, which can be referred to as the exposome, encompasses all the external factors we’re exposed to over a lifetime—pollutants, allergens, and the ongoing quality of air inside our buildings. These exposures influence our health, often in profound ways, making thoughtful decisions in materials and systems a cornerstone of healthy living and working spaces.

Insulation, while often considered purely for energy efficiency, plays a critical role in shaping the indoor environment. Poor insulation can emit harmful particles and chemicals, exacerbate mold issues, or fail to support adequate ventilation. In contrast, health-focused insulation choices can significantly improve indoor air quality (IAQ), reducing exposure to allergens and irritants, and help prevent conditions that can lead to sick building syndrome (SBS) and building-related illnesses (BRI).

This article explores how the asthma & allergy friendly® Certification Program evaluates a range of fiberglass insulation products, ensuring they contribute to healthier indoor environments. It also highlights the five pathways by which insulation can impact health, how certified insulation mitigates these risks, and why CERTIFIED fiberglass insulation is an ideal choice for achieving better air quality in workplaces.

Asthma & Allergy Friendly® Certification: What It Means

For an insulation product to earn asthma & allergy friendly® certification, it must meet five essential criteria:

- Ingredient Review: All components are assessed for sensitizing materials.

- VOC Limits: Volatile organic compound (VOC) emissions must remain below strict thresholds to reduce respiratory irritation.

- Mold Resistance: The product must demonstrate resistance to mold growth under rigorous testing conditions.

- Low Dust and Particle Emissions: Insulation must not significantly raise dust or airborne fiber levels during a room disturbance.

- No Formaldehyde-Based Binders: Products containing formaldehyde-based binders or harmful flame retardants are not eligible.

The certification process is entirely independent, relying on third-party testing to ensure compliance with these standards. This approach focuses on mitigating common asthma and allergy triggers, enhancing IAQ, and prioritizing consumer health.

The Five Health Pathways for Insulation

When developing certification standards, the asthma & allergy friendly® program evaluates insulation based on five key exposure pathways:

1. Dust and Fiber Emissions

Fiberglass insulation can release small particles and fibers, particularly following installation during room disturbances. These particles can irritate the eyes, nose, throat, and lungs, with potential exacerbation of symptoms in people with respiratory conditions.

Testing involves installing insulation in an environmental chamber to match the product’s main application, simulating room disturbances, and measuring airborne particles and fibers. Certification requires that dust, particle, and fiber levels remain below specific thresholds, ensuring minimal respiratory impact during and after installation.

2. VOC Emissions

Volatile organic compounds (VOCs) are chemicals that easily evaporate at room temperature. Common sources include paints, adhesives, and some building materials, with potential to cause headaches, respiratory irritation, and dizziness.

To certify insulation, VOC emissions are measured in an environmental chamber over 14 days, with readings taken at 24 and 336 hours. Certified products must demonstrate consistently low VOC emissions, ensuring healthier indoor air for occupants.

3. Mold Resistance

Mold thrives in damp environments and can be both an irritant and allergen. Prolonged exposure to mold spores can cause nasal congestion, respiratory inflammation, and allergic reactions. Although fiberglass insulation is often claimed to resist mold, studies show it can support mold growth under certain conditions. To confirm resistance, insulation samples are inoculated with mold spores and subjected to high humidity and temperature for four weeks. Certified products must resist mold growth compared to control materials.

4. Chemical Composition

The chemical composition of insulation is critical, as some materials can irritate skin and respiratory systems or cause long-term health issues. A detailed assessment ensures that any potentially sensitizing chemicals are present at relatively low levels.

One particular concern in insulation is the presence of flame retardants. Halogenated flame retardants, such as HBCD, have been linked to toxic indoor air and environmental harm. Certified insulation must avoid such chemicals, relying instead on safer alternatives. Additionally, formaldehyde-based binders, which can emit harmful VOCs, are prohibited.

5. Specialized Applications: Erosion and Corrosion

Specialized insulation products like duct liners, duct boards, and pipe and tank insulation pose unique risks. Erosion of duct insulation can release particles into ventilation systems, while pipe insulation must not contribute to corrosion. Certification requires these products to pass rigorous erosion and corrosion tests, ensuring their long-term effectiveness.

Why Fiberglass Insulation?

Fiberglass insulation is currently the only insulation certified in the asthma & allergy friendly® program. This material offers several advantages:

- It avoids the halogenated flame retardants commonly found in other insulation types.

- It is cost-effective, providing a healthier option that is accessible to a wide range of consumers.

- It inherently supports mold resistance when properly manufactured.

By focusing on fiberglass, the certification program ensures that products meet the highest standards of health and performance while remaining practical for everyday use.

Building Healthier Indoor Spaces

Insulation is just one element of creating healthier indoor environments, but achieving better indoor air quality (IAQ) or indoor environmental quality (IEQ) requires a comprehensive approach that includes other certified products like paint, flooring, and air cleaning systems. Certified paints and flooring ensure low VOC emissions and minimal allergen release, while certified air cleaners—whether portable or whole-home systems—effectively reduce airborne allergens, particles, and VOCs. Similarly, the relative humidity in our homes can be controlled by dehumidifiers/humidifiers, depending on the season and environment. These solutions, combined with proper ventilation systems such as advanced HVAC setups, can help dilute indoor pollutants and create safer, more comfortable spaces. Together, these measures work to prevent sick building syndrome and building-related illnesses, promoting health and productivity in every indoor environment.

Education Through the iAIR Academy

The iAIR Academy plays a vital role in bridging the gap between science and practical application. By offering tailored educational programs, the academy equips professionals and consumers with the knowledge to make informed decisions about materials and practices that impact IAQ. Courses focus on understanding the science of building materials, ventilation strategies, and the importance of certifications like asthma & allergy friendly®. With real-world case studies and interactive learning, the academy ensures participants grasp both the “why” and the “how” of creating healthier indoor environments.

Conclusion: A Commitment to Healthier Choices

Every decision in building design and maintenance contributes to the exposome, shaping the indoor environment and, ultimately, our health. By choosing CERTIFIED insulation, implementing effective ventilation, and addressing IAQ comprehensively, we can significantly reduce exposures to harmful pollutants and allergens. Through programs such as the asthma & allergy friendly® Certification Program and educational initiatives like the iAIR Academy, we are empowering individuals and industries to make healthier choices. Fiberglass insulation certified under this program exemplifies how thoughtful product design and rigorous testing can contribute to safer, more comfortable spaces for everyone.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.png?height=200&t=1744809118&width=200)