Optimizing Below-Grade Insulation

How Polyiso Enhances Building Performance

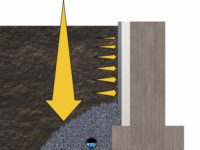

Proper site preparation and grading for effective below-grade insulation. All photos courtesy of Rmax.

.png?t=1739312058&width=1080)

.png?t=1739312058&width=150)

Below-grade structures, such as basements and foundations, present unique challenges in managing moisture, ensuring thermal efficiency, and maintaining structural integrity. Optimizing construction practices in these areas is essential because it directly affects the longevity and performance of the building envelope. Effective insulation strategies that enhance energy efficiency, prevent moisture intrusion, and contribute to a durable and sustainable structure are crucial in this process.

While polyiso is commonly used for roofing and above grade walls, the material is also ideal for below-grade insulation when manufactured with a water-resistant facer. Its high moisture resistance and closed-cell structure prevent water absorption, ensuring that the insulation properties remain intact even in challenging underground conditions.

This characteristic makes polyiso an excellent choice for below-grade insulation, where moisture resistance is crucial to maintaining the integrity and performance of the building envelope. Additionally, polyiso's superior R-value means that 25% less material is needed to meet the same thermal resistance requirements as XPS; 1.5” of polyiso achieves an R-10, and 2.3” achieves an R-15. By comparison, 2” of XPS is needed for R-10, and 3” for R-15.

The Importance of Below-Grade Insulation

Below-grade insulation is a critical component of modern construction, playing a vital role in maintaining the thermal integrity of a building. It regulates temperature, reduces energy consumption, protects against moisture, and prevents the waterproofing membrane from being damaged during the backfill process. Given the harsh conditions that below-grade applications often face, such as constant contact with soil and exposure to groundwater, selecting the right insulation material is crucial.

Polyiso insulation, with its closed-cell structure, high moisture resistance, and durable facers is particularly well-suited for these conditions. Its ability to maintain insulation properties even when exposed to moisture ensures that the thermal integrity of the building is preserved over the long term.

Understanding Thermal Performance

Thermal performance is a key factor in below-grade construction, particularly in areas with extreme temperatures. Insulation is rated by its R-value, a measure of resistance to heat flow. The higher the R-value, the better the material insulates. However, in the confined spaces typical of below-grade applications, achieving the desired thermal performance with minimal thickness is often important.

Polyiso excels in this regard, offering a higher R-value per inch compared to many other insulation materials. This allows builders to achieve the required thermal resistance without adding unnecessary thickness, which can be particularly important when space is at a premium. By using polyiso, contractors and builders can ensure that the interior environment remains stable, reducing the need for additional heating or cooling and thereby lowering energy costs.

Moisture Management

One of the most significant challenges in below-grade construction is managing moisture. Water can penetrate through the soil and into the building envelope, leading to issues such as mold growth, structural damage, and reduced insulation effectiveness. Therefore, the insulation material chosen for below-grade applications must resist moisture effectively.

Polyiso, with its closed-cell structure, provides superior resistance to moisture intrusion. Unlike some other insulation materials, polyiso does not absorb water, which means it retains its insulating properties even in wet conditions. This makes it an ideal choice for areas prone to flooding or with high groundwater levels. Additionally, the use of polyiso can reduce the need for additional moisture barriers, streamlining the construction process and reducing costs.

Structural Considerations

Maintaining the structural integrity of below-grade applications is another critical consideration. Insulation materials used in these areas must withstand the pressure exerted by the surrounding soil and any water that may accumulate. A 25 psi compressive strength is the typical standard for effective below-grade insulation in commercial and residential foundations, ensuring that the material does not compress or deform under load.

Polyiso insulation, known for its high compressive strength, meets these demands, ensuring that it can bear the pressure from the surrounding earth and water without losing its shape or effectiveness. Additionally, polyiso's compatibility with various structural designs makes it a versatile option for different types of below-grade applications in commercial and residential construction.

Installation Best Practices

The effectiveness of below-grade insulation depends not only on the material itself but also on the quality of its installation. Proper installation techniques are crucial to achieving the desired thermal and moisture resistance performance. Here are some best practices for installing below-grade insulation:

- Prepare the Site Properly: Before installing insulation, ensure the site is properly prepared. This includes grading the soil to direct water away from the foundation and ensuring that the surface is clean and free of debris.

- Place the Insulation Correctly: Install insulation in a continuous layer around the perimeter of the foundation, extending below grade to protect against heat loss and moisture ingress. Polyiso, with its ease of installation and ability to provide continuous insulation, is ideal for this purpose. Care should be taken to avoid gaps or discontinuities in the insulation, as these can compromise its effectiveness.

- Protect the Waterproofing During Backfilling: During the backfilling process, polyiso insulation will protect the waterproofing membrane from damage. Polyiso’s durable facers provides and extra layer of protection during this process.

- Regular Inspection and Maintenance: After installation, regularly inspect and maintain the insulation system to ensure its long-term performance. Address any damage or degradation promptly to prevent further issues.

Sustainability and Environmental Impact

For the construction industry, sustainability is a growing concern. The insulation material used in below-grade applications should contribute to the building's overall sustainability. This includes factors such as the material's embodied energy, its impact on the building's energy efficiency, and its potential for recycling or reuse at the end of its life.

Polyiso is often recognized for its environmental benefits. Its high R-value contributes to the building’s energy efficiency by reducing the need for heating and cooling. This not only lowers the building's operational energy consumption but also reduces its carbon footprint. Additionally, polyiso can meet the same R-value requirement with 25 percent less material than XPS. Using 1.5” of polyiso instead of 2” of XPS for an R-10, means 25 percent less material produced, warehoused, and transported. It’s not necessary to send 4 trucks of XPS to a jobsite when 3 trucks of polyiso will do the job.

As an overview, optimizing construction practices for below-grade applications requires a thorough understanding of the challenges and opportunities presented by this unique environment. Polyiso insulation, with its high R-value, moisture resistance, and compressive strength, is an excellent choice for these applications. By selecting the right insulation materials and following best practices for installation, builders, contractors and architects can ensure that below-grade structures are energy-efficient, moisture-resistant, and structurally sound.

As the construction industry continues to evolve, staying informed about the latest developments in insulation materials and techniques, including advancements in polyiso technology, is essential for optimizing below-grade construction practices.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.png)