ATAS Introduces Two Accessory Items

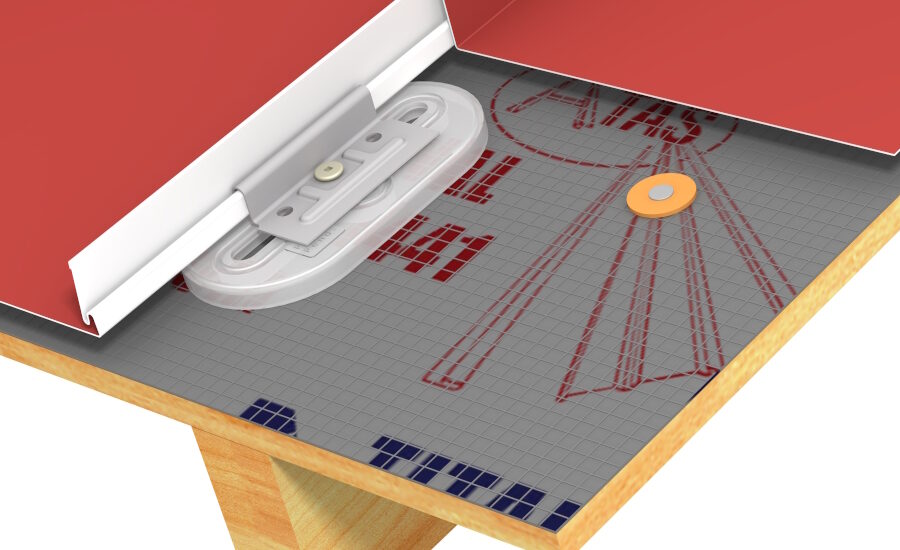

The ATAS ASV (above sheathing ventilation) shim has been rebranded to become the ASV/TB shim. TB is for thermal break, which the product achieves, along with providing ventilation above the sheathing. By incorporating ASV/TB into a roof design, it ventilates the air space between the roof cladding material and the subassembly and roof deck. This allows for the temperature of the roof cladding to be closer to the outdoor ambient temperature, and it reduces heat gain passing through the roof assembly in the summertime, as proven by studies and testing performance sponsored by the MCA (Metal Construction Association) at Oakridge National Lab. ASV/TB also adds insulation value during the winter and minimizes the effect on condensation between the roof layers and wall assembles.

A thermal break is an insulating material that is strategically placed between highly conductive structural components within the building envelope, acting as a thermal barrier to interrupt the flow of thermal energy. ATAS’ ASV/TB reduces the transfer of heat from one side of the structural component to the other, acting as a thermal barrier and significantly enhances the energy efficiency of a roof or wall assembly.

Incorporating ASV/TB into a roofing or wall cladding system is one of several components that can contribute to a better performing roof or wall, and a more energy efficient building, resulting in energy cost savings and a means to reduce carbon impact on the environment.

For underlayments, ATAS has added PanelShield™ SA, by VaproShield, to their product offering. This wall panel underlayment offers many positive attributes:

- Creates a water resistive air barrier when applied outside of the wall sheathing

- Cost effective permeable polyester air barrier WRB (water resistant barrier) system

- Does not require primer

- 12 months UV and weather exposure, ideal for long-term projects

- Tough and durable, withstands aggressive construction handling

- Tenacious adhesion to substrate withstands cross-country transport

- Aggressive adhesive firmly grips to OSB and other common substrates

- Superb drying capacity, 26 perms

- All weather installation – including below freezing 20°F (-6°C)

- Used for transitions, rough openings, fenestrations, and full-wall applications

- Air Barrier, passes ASTM E2178 and E2357

- Fire Rated, Class A to ASTM E84

- 20-year warranty

PanelShield SA joins three other underlayments offered by ATAS (all of which are roof underlayments):

- SlopeShield® Plus, by VaproShield, self-adhered roof underlayment – Recommended for use with the ATAS ASV/TB Shim to offer a highly vapor permeable roofing underlayment air barrier material to allow the entire roof assembly to breathe while the ASV/TB shim provides for above sheathing ventilation and increased energy efficiencies.

- ATA-Shield roof underlayment – A self-adhering underlayment designed specifically for use under metal roofing. This membrane is well suited for use where a WRB is required. It is formulated to withstand the high heat environment generated by some metal roofing systems. ATA-Shield is composed of an unreinforced polymer-modified bitumen material adhered to the underside of a polymer-coated synthetic woven material.

- ATA-Guard roof underlayment – A highly engineered, mechanically attached, coated woven synthetic roofing underlayment for sloped roofs. It can be used under all types of primary roofing materials and is approved as an alternative replacement for Type 15 or Type 30 asphalt roofing felt. ATA-Guard is five times lighter and 25 times stronger than 30-pound asphalt. It is a 100% asphalt free reinforced underlayment. Advanced polymers are combined to produce a film that is unaffected by water and resistant to UV for up to six months.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.png?height=200&t=1730907904&width=200)