Moisture Surveys and Roofing Forensics

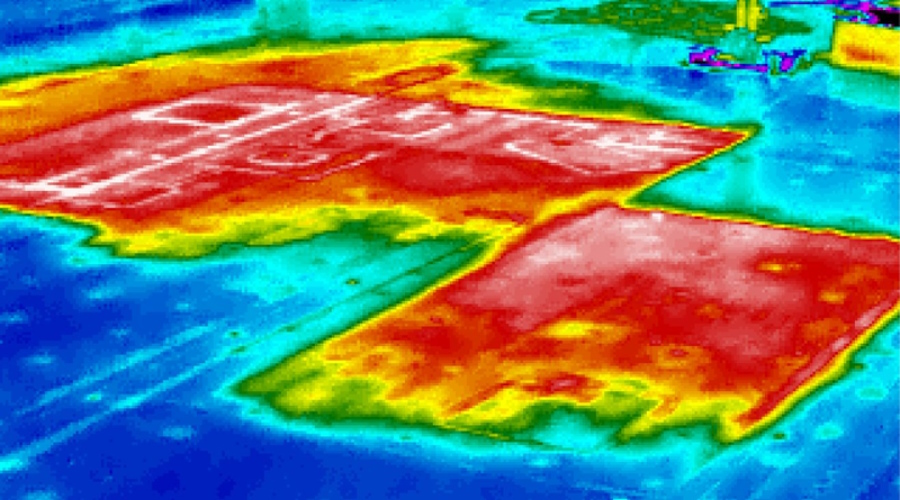

Infrared Image (heat picture) of Moisture Damaged Roofing. Image courtesy of IR Analyzers

Forensic and maintenance inspections of roofing systems provide huge benefits to all stakeholders. Regular visual inspections can ensure early detection of problems such as leaks, ponding water, punctures, cracks, or membrane damage. Proactive approaches allow for prompt repairs, preventing more extensive damage.

Accurate evaluation of roof conditions will assist in making smart maintenance and repair decisions. These inspections play a critical role in reducing leak damage and disruptions caused by roof leaks, and help extend the lifespan of this critical asset.

Roof moisture surveys assist by providing early detection of moisture problems and are an invaluable addition to the inspection procedure. Moisture surveys are unique procedures that provide an accurate assessment of the true moisture conditions in the roof. Building owners, consultants, contractors and maintenance teams utilize moisture surveys to help prevent structural damage and mold and mildew growth, and reduce repair and maintenance costs.

Independent third-party non-destructive moisture surveys are an essential part of a comprehensive inspection program. When conducted by Certified and experienced technicians they are quick, accurate and cost-effective. Best practice is to verify the survey findings with selected core samples whenever possible.

There are three different methodologies that can be utilized to provide accurate roof moisture testing: Infrared, Nuclear, and Capacitance / Impedance. These techniques use different detection technologies, and each has its advantages and limitations.

It’s important to be aware that all non-destructive techniques have the potential for the instruments to report both false positive and false negative conditions. While Infrared Testing is the most common moisture survey procedure, it has accuracy limitations. There are many situations where Infrared Thermography is not able to provide accurate moisture detection on certain sections of a roof. In addition, there are many roofing assemblies where the entire roof will not be able to be accurately tested with Infrared, and Nuclear or Capacitance instruments will be required to ensure reliable results.

Because of the huge variety of assemblies that need testing, it’s important to understand how these technologies work to pinpoint moisture damage, and the advantages and disadvantages of each procedure.

1. Infrared Moisture Surveys

When the conditions are set up properly (sunny day, dry membrane surface, low winds), moisture damage will display on the roof as “hot spots” (warmer thermal anomalies) compared to the cooler temperatures of surrounding dry roof.

Infrared Surveys can provide 100% membrane coverage, and they often take the least amount of survey time, especially if there is a relatively small amount of moisture damage. However, infrared scanning requires membrane exposure to sunlight and areas of the roof that are shaded by equipment, trees, adjacent buildings, etc. will not develop the warm thermal anomalies needed to identify moisture. Also, the infrared camera cannot see through roofing with rock ballast (1-1.5” rocks) and these assemblies must be inspected with nuclear technology. Another significant limitation of infrared cameras is that they can only “see” moisture damage when there is sufficient IR radiation emitted from the roof surface for the camera to image moisture damage. Newer reflective membranes (cool roofs) and coatings are poor infrared radiation emitters, and the wet areas often do not display the warmer thermal patterns needed for identification. This results in failure to detect wet areas (false negative imagery). Highly reflective membranes must be tested with Nuclear or Capacitance methods to ensure accurate results.

2. Nuclear Roof Moisture Surveys

Nuclear moisture surveys operate on the principle of neutron moderation. Fast neutrons emitted by a tiny radioactive source are slowed by hydrogen in the materials. These slowed neutrons are counted and presented as relative hydrogen readings. When the baseline levels of hydrogen in dry materials are established, elevated hydrogen levels indicate the presence of water (H2O).

Nuclear Testing can produce highly accurate results on roofs when infrared imagery may be inaccurate or inconclusive. It is also a powerful backup technique when performing Infrared Testing. Because it does not rely on the development of thermal images, nuclear testing can be employed on reflective roofs when Infrared Testing will not yield reliable results. It can also be an excellent backup / cross-check for Infrared Testing in areas of the roof that are shaded or where the infrared imagery is inconclusive.

A disadvantage of Nuclear Testing is that readings are taken on a grid, and moisture detection only occurs in the area directly under the gauge. However, nuclear readings are exceptionally straightforward and reliable and can contribute significantly to accurate test results. Another advantage of nuclear is that surveys are performed during the day instead of at night, which can solve problems with difficult access or safety concerns.

3. Capacitance/Impedance Surveys

Capacitance Testing is another excellent addition to the roof moisture survey toolbox. The Capacitance meter attempts to pass an electrical current through the materials. Areas of moisture damage will conduct this current, while dry areas will resist the current flow. Like Infrared, Capacitance Testing surveys 100% of the membrane. The instruments reliably locate the boundaries between wet and dry materials. Unfortunately, it can’t be applied to electrically conductive membranes like EPDM.

Capacitance is an excellent choice on highly reflective surfaces because it is not subject to the false negative readings common with Infrared Testing on these assemblies. Like Nuclear, it is helpful in situations where daytime testing is preferable because of access or safety concerns. Along with Nuclear, Capacitance technology is an excellent backup / cross-check for Infrared Testing in areas that are shaded or where the infrared imagery is inconclusive.

Summary

Securing the longest, most trouble-free service from a roof system can require both maintenance and forensic inspections, and roof moisture surveys are an invaluable addition to these inspection procedures. It's important to note that while moisture surveys can provide vital information about the true condition of the assembly, accuracy of the testing is critical. All stakeholders will be relying heavily on the validity of the moisture survey test results.

If the survey reports false positives, the condition of the roof will be misrepresented as overly water damaged. Possibly of even greater concern is the potential for false negative findings when the moisture damaged areas are not detected.

Experienced and Certified independent third-party providers of moisture testing services will utilize test techniques or often a combination of test techniques that will produce the greatest accuracy. Combining highly accurate moisture surveys with comprehensive visual inspections will be hugely beneficial to all stakeholders. The data obtained from moisture surveys greatly improves decision making and assists in targeting resources to the most cost-effective solutions.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!