Since it was created in the 1970s, continuous insulation continues to serve as a high-performance solution for both residential and commercial construction that must adhere to changing, more rigorous code requirements. Plus, products that combine insulation and sheathing have given builders more options, especially those affected by the lumber shortages over the past two years. Todd Gluski, director of marketing for Ox Engineered Products, an industry leader and innovator in continuous insulation, offers insight and perspective on continuous insulation and its role in 21st-century construction.

Q: What is continuous insulation?

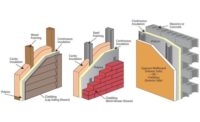

A: Continuous insulation is insulation that is installed continuously across studs, designed to eliminate thermal loss, increase energy efficiency, and when equipped with a weather barrier, keep the outside elements out.

Q: What are the biggest performance advantages to using continuous insulation?

A: On residential, multi-family, light commercial, or commercial jobs, the greatest payoff is the elimination of thermal bridging. Eliminating thermal bridging provides long-term energy savings for a structure by reducing reliance on heating and air conditioning.

Another key advantage to using continuous insulation is a decreased risk for condensation within the walls. Continuous insulation is installed outboard the studs, which moves the dew point to the outside of the sheathing and further toward the exterior of the building. By doing so, the risk of condensation build-up within a wall assembly is greatly reduced, minimizing the risk for deterioration or mold growth within a wall.

Q: How do continuous insulation products provide this level of performance that you describe?

A: The level of performance will vary based on the material used to create an insulating product. Products that are made from polyisocyanurate, which is a closed-cell foam, differ from expanded polystyrene (EPS) foam products. With polyiso insulation, moisture and water will not penetrate through, keeping the wall cavity and studs dry. Polyiso foam possesses excellent energy conservation qualities as well.

Q: Aside from their polyiso construction, what other qualities make these types of insulation products a good choice for builders?

A: There are plenty of benefits that come with choosing polyiso continuous insulation, and even more when you choose integrated products specifically. For example, Ox Engineered Products offers a 4-in-1 structural continuous insulation product that delivers a range of benefits for the builder. The product is a comprehensive solution addressing multiple layers of the exterior wall all in a single solution. Its layers consist of structural sheathing, continuous insulation, an air barrier, and a water-resistive barrier. These combined layers eliminate the need to install sheathing and then insulation separately, and it reduces the number of passes an installer needs to make around the structure because the air and water barriers are also included.

Q: How easy is continuous insulation to install? Does it lighten the burden for installers?

A: Builders have options when it comes to the installation of continuous insulation products depending on their preference and the type of studs used to build the home. For wood studs, builders can use 16-gauge staples or standard framing nails for Ox products. Screws can be used when fastening to metal studs. For Ox products specifically, seam tape is used at panel edges for a comprehensive seal. However, seam tape is not required to cover fastener penetrations because of the self-sealing characteristics of polyiso thermoset foam, which saves builders time during installs.

All in all, continuous insulation is lightweight, easy to install, and reduces the number of separate layers needed to build exterior walls.

Q: Lumber prices are coming back down to earth, but how do Ox products help alleviate supply chain issues caused by the COVID-19 pandemic?

A: The answer is actually twofold. For one, you can use products such as OX-IS – 4-in-1 structural continuous insulation – with 2x4 framing as opposed to 2x6s and still achieve a high R-value. This lightens some budgetary concerns by enabling builders to purchase a smaller and less expensive lumber package. Builders should also keep an eye out for products that combine structural sheathing and insulation in one, such as OX-IS. During the pandemic, many builders turned to Ox because they could not get OSB sheathing and they needed an alternative material.

Many of those builders also chose Ox’s ThermoPLY®. ThermoPLY is a structural sheathing product equipped with an exterior facing surface and a water-resistive coating. It has a comparable shear value to a 7/16” sheet of OSB, making it an excellent sheathing alternative. It is also lighter and more affordable than OSB, which was especially important during lumber price hikes caused by the COVID-19 pandemic.

Q: How do you see continuous insulation continuing to play a role in the building and construction industry in the coming years?

A: For every construction job, stakeholders look at three key factors – time, money, and sustainability. How can I deliver a quality solution in a cost-competitive way on time and on budget while simultaneously meeting energy efficiency requirements? This is particularly true when it comes to energy savings over the long haul for a residential home or a commercial building. Continuous insulation cuts down on installation time, and that often translates into appreciable savings on a construction job. When you also consider that continuous insulation can help a builder achieve desirable R-value for a structure, continuous insulation will continue to move up in the consideration set for architects, builders, and contractors.

.jpg?1637160452)