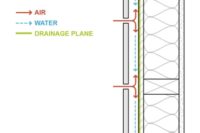

Fluid-applied, Bulk Water Management Membrane

Masonry Veneer Installation System Water Crack Isolation

LATICRETE, a leading manufacturer of globally proven construction solutions for the building industry, has launched Masonry Veneer Installation System (MVIS™) Water Crack Isolation (WCI). MVIS WCI is a premier crack isolation solution that enhances longevity thanks to its outer protective shield when used with LATICRETE® air barriers or other air barrier systems. The product is a single-component, load-bearing, fluid-applied, bulk water management and crack isolation membrane that produces a seamless, monolithic elastomeric coating that bonds directly to a wide variety of concrete and cement backer board substrates due to its unmatched strength.

“MVIS WCI was carefully engineered to achieve peace-of-mind for the end user and guard against the harshest elements, making it a necessity to avoid costly repairs down the road,” said Dustin Prevete, LATICRETE Senior Product Manager. “As LATICRETE continues to evolve in the masonry veneer market, MVIS WCI provides an effective solution to provide superior crack isolation, excellent bond strength and water resistance, preventing in-plane movement from transmitting through finished materials and preventing bulk water migration through the full system.”

MVIS WCI is a low-VOC, self-curing, water-based formula containing antimicrobial technology that helps prevent mold and mildew formation. Used in construction where air barrier and drainage planes are required to improve building efficiency and durability, MVIS WCI contains no solvents, is non-flammable and exceeds A118.12 standards.

The new membrane has a light color which makes for an easier inspection process. In addition, it also features color changing technology to visibly show when it has cured and bridges up to ¼-inch (6 mm) gaps on sheathing board joints with waterproofing and anti-fracture fabric. MVIS WCI is available in a five-gallon (18.9 L) pail and provides roughly 250 feet (76.2 m) of coverage.

For more information, visit laticrete.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!