Streamlining Exterior Air Barrier and Insulation Requirements for 2015 IECC Codes

The International Energy Conservation Code (IECC), produced by the International Code Council (ICC), sets the national standard for energy codes and is observed across many states and municipalities in the United States. The ICC produces both the IECC and the International Building Code to guide energy efficiency, which provide opportunities for both businesses and homeowners to conserve resources and save money upon adoption.

With updated codes released every three years, state and local officials analyze and consider the potential benefits for their jurisdictions in adopting these newer codes. Challenges to adopting new codes include training agencies to recognize and enforce the code through official permitting and inspection as well as educating the builders and general public about why the codes are important best practices for the future of the community.

Since its inception in 1994, the ICC has made great strides in finding ways to improve commercial building. The U.S. Department of Energy analysis of the 2015 IECC code recognized an 11.5 percent increase in energy savings for commercial buildings over the 2012 energy codes at the aggregate national level. The 2015 IECC update showed stronger emphasis on climate zones and introduced more stringent mandates for the opaque building envelope, including mandating a continuous air barrier for all climate zones except 2B. Since 2012, IECC code has also included requirements for increased insulation or the use continuous insulation to manage thermal bridging for commercial buildings.

As the codes push baseline standards for the industry higher, it’s important for those at the frontlines to see the opportunity in meeting and exceeding energy code requirements for their business. Selling points for better air sealing and continuous insulation include increased comfort and long-term durability with a decrease in operating costs from heating and cooling. Additionally, new innovations in the industry create faster, more efficient ways to effectively fulfill the requirements in the assembly. The following case study will consider a brewery project by CAJOTA Contracting.

Building With 2015 Energy Code Mandates

CAJOTA Contracting is a commercial contractor that specializes in mid-rise commercial buildings in the Pittsburgh, Pennsylvania area. In 2018, the state of Pennsylvania adopted the 2015 IECC codes, placing the state in the top half of the country for energy efficiency regulations. As a result, the CAJOTA Contracting team knew they needed streamlined methods to meet the continuous air barrier and increased insulation requirements while maintaining speed and quality in their projects.

One CAJOTA Contracting project built under the new code implementation, for example, is the Iron Rock Tap House located in Westmoreland County, just outside Pittsburgh. The new building is two stories high and framed with light gage steel. Pennsylvania is in IECC climate zone 5A, which is designated as cold. As a result, the 2015 codes call for R-7.5 continuous insulation on metal framed commercial buildings, according to Table C402.1.3 in the 2018 International Energy Conservation Code.

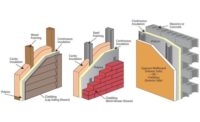

There are a few ways the contracting team could approach the wall assembly to achieve code. Some examples are:

1. Install sheathing, a mechanically attached weather-resistive barrier, and exterior insulation board.

2. Install sheathing then exterior insulation board with taped seams to function as the weather resistive barrier.

3. Install, from the metal studs out, one layer of sheathing with integrated weather resistive barrier and built in rigid foam insulation and finished with tape at the seams.

For this project, the CAJOTA team used option three, opting for R-9 ZIP System R-sheathing, which has a 2’-inch panel thickness and R-value of 9.6 (foam plus OSB), completed with ZIP System flashing tape on the seams, because the products—an integrated WRB sheathing panel with a layer of foam laminated to the interior face and finished with advanced acrylic tape—complete the exterior thermal and air barrier requirements in one step.

“With ZIP System R-sheathing, nothing else was required,” D’Andrea said. “Once the panel system went on, we taped the seams, windows, corners and that completed the barrier required for the building.” D’Andrea said, if they hadn’t used ZIP System R-sheathing, the assembly would have been an exterior single board, blown-in insulation, and a fluid-applied air-and-water barrier. Although more widely used in wood-framed residential buildings, it is becoming increasingly common to adopt high-performance products such as ZIP System R-sheathing for light gage steel-framed commercial builds.

“We knew ZIP System R-sheathing mostly as a residential building product,” said CAJOTA Contracting project estimator Adam D’Andrea. “But after we saw the product samples and R-value the product would provide, we sent it to the architect to spec. They saw the benefits and approved the system for our steel-framed commercial use.”

In the CAJOTA tap house project, the metal framing provided the necessary structural support for lateral shear loads, so it did not require the R-sheathing system to provide structure. However, when used in wood-framed construction, the all-in-one product solution provides not only integrated air, water and thermal barriers, but contribute shear load capacity as well. Shear values, along with fastening schedules to meet wall bracing can be found on InsulateYourBuild.com for this product.

An all-in-one board can also be used to provide a nail base for detail cladding. The tap house has a cultured stone finish, which requires a fastening system for installation. D’Andrea said they attached felt paper, roofing nails and wire mesh to the ZIP System R-sheathing wall followed by a scratch coat on the wire mesh. To complete the exterior, a finish installation company applied cultured stone and mortared the joints. The fastening system connected to the sheathing prevented the stones from toppling over during the install process.

“We were concerned about the stone finish,” D’Andrea said. “We weren’t sure if the system could hold that amount of weight. We worked with the engineering department to determine load capacity and the stone system on front face was approved.”

With an easy installation process for meeting more stringent code requirements, D’Andrea said he would recommend an all-in-one insulation and air barrier product like ZIP System R-sheathing for future commercial building projects.

Raising the Building Efficiency Bar

Ultimately, the goal of energy efficiency is not energy efficiency itself, but the host of other priorities such as the health, comfort, durability and cost-savings the building can offer the people occupying and operating it. Energy efficiency building codes for the building envelope, at their core, are simply considering the ways air, moisture and heat flow inside and out of a building and how the people who live and work in that built environment can better control those elements. Builders, whether by code or by choice, building with continuous insulation and continuous air barriers will likely see greater control and longevity in the finished product. From this perspective, it is perhaps easier to see the business opportunities and selling points of meeting and exceeding energy efficiency codes for clients, whether or not they know yet to ask for it.

When evaluating products for the building envelope, considering how well and how efficiently a product meets those standards is critical. For example, despite a product’s higher initial cost, it could be evaluated next to potential labor savings. New integrated envelope products reduce the risk of error by reducing installation steps and can reduce installation time by combining several previously sequenced steps into a single panel install with seam sealing and flashing detailing.

The 2015 IECC codes are being introduced into state and municipal law around the country, although not always in full. Regardless of official adoption, current products and building science practices make it easier to push the envelope and raise the bar.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.jpg?height=200&t=1642705383&width=200)