Three new stations in the Toronto Transit Commission Line 1 Extension employed inverted roof membrane assemblies to achieve cool roof and longevity requirements. Unlike most inverted roof membrane assemblies, these roofs are not flat, nor high atop a building out of public view. At each location the roof is a key design feature utilizing curves in multiple directions to create the architect’s vision. The performance and longevity of each roof system was a top priority to meet Toronto Green Standards at each station.

Architects and roofing contractors agree the longevity of the inverted roof membrane assembly is determined by protecting the membrane from UV exposure and thermal cycles. Increasing membrane life expectancy is achieved by adding layers of material above the membrane. In the most basic assembly, the layers above the membrane may be insulation, filter fabric, and ballast. For a vegetated roof, the layers may be insulation, drainage space, root barrier, filter fabric, and a planting medium.

When the roof curves, the materials and methods used to protect the membrane of the inverted roof assembly grow increasingly complex and differ from project to project. The structure below the membrane is no longer flat with gentle slopes to facilitate drainage. For each of the TTC roof designs, the steel deck was segmented to approximate the curvature of the roof. This segmented structure opposite the curved finished roof profile created an interstitial space with varying heights.

York University Station

At York University Station, the 1,140 square meter inverted roof with flowing compound curves ended in an undulating perimeter gutter system. Adamson Associates, architect of record, credits the accuracy of the completed station to the early design and budget rounds prior to Construction Documents that closely monitored project data. Additionally, “at each CD submission costing was incorporated to help stay the course and prevent surprises,” said Estelito So of Adamson Associates.

Materials used for the inverted roof membrane assembly at York University Station, from the segmented steel deck were: Densdeck Prime, Soprema Elastcol primer, Soprema Sopralene base sheet, Tremco Butyl tape, Radius Track pre-curved hat channel, track and studs connected by varying height angle clips, Roxul Rockboard semi rigid insulation, Kalzip Aluminum Panel standing seam, and ColorGad snow retention system. The roofing contractor, Bothwell-Accurate, leveraged technology, tech savvy partners and a Kalzip certified in-house installation team to deliver their scope of work under a compressed schedule. As soon as the steel deck was installed, and the roof area was turned over to Bothwell, they executed a 3-D scan of the entire roof to identify as-built conditions and precisely locate the roof deck. To bridge the gap from the roof deck to the smooth finished metal roof, Bothwell engaged Radius Track Corporation to design, engineer and fabricate a light-gauge sub-system using the 3-D scan along with construction documents and supplemental information.

While Bothwell installed the sheathing board and 2-ply modified bituminous membrane, Radius Track designed, engineered and fabricated the sub-system to fit the interstitial space and set the geometry for the custom curved Kalzip standing seam metal roof. The sub-system began with hat-channel fastened to the superstructure through the 2-ply membrane. The installation team unitized pre-curved track and stud profiles onsite and hoisted them into place. Each unitized section was fastened to a specific hat-channel using a clip angle of appropriate height. With the geometry set, standing seam metal roof clips were attached to the track-stud units.

The entire system was closely coordinated with the membrane manufacturer, Soprema, to develop a warranty approved method. Around and below the pre-curved framing, Roxul mineral wool insulation covered the 2-ply membrane system. In addition to setting the geometry, the light-gauge sub-system provided an airspace between the insulation and standing seam panels. The high albedo standing seam metal panels reduced the overall solar heat gains of the roof by reflecting a large amount of the sun’s rays. This inverted approach, which combined thermal protection via insulation and airspace, also provided protection from the sound of rain or hail hitting the standing seam metal roof—and protected the 2-ply membrane system from thermal and UV degradation.

The high-performance roof system installation was coordinated virtually through 3D model sharing before the sub-system or roof panels were fabricated. Radius Track and Kalzip coordinated and sequenced the sub-framing fabrication, standing seam panel production and delivery to facilitate continuous installation. The curvilinear shape of this inverted roof membrane assembly required the design and construction teams to leverage advanced materials and methods to provide lasting performance and deliver geometric precision.

Highway 407 Station

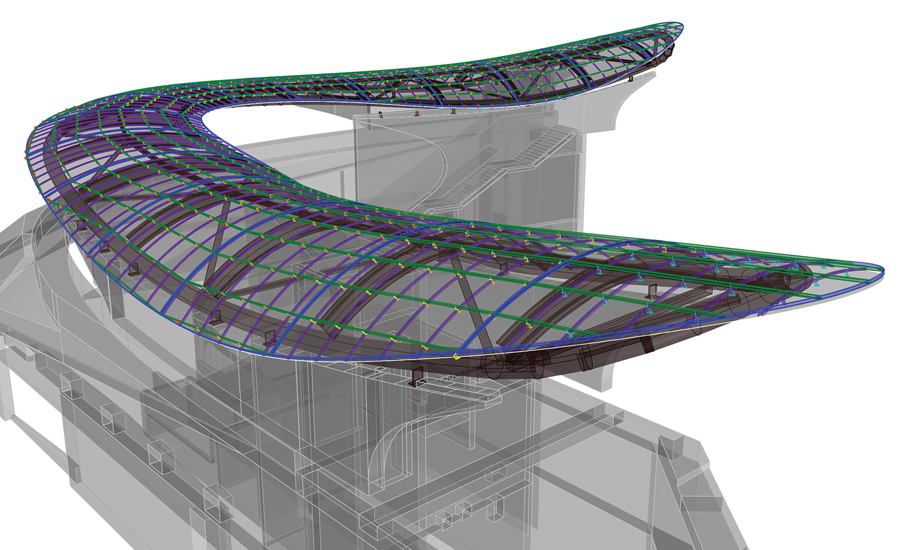

Heading north from York University, the Highway 407 station is a multi-modal transportation hub combining subway, regional rail and bus transit services. The roof of this transit hub curves and stretches to provide protection from the elements. Materials used for the inverted roof membrane assembly at the Highway 407 Station starting from the segmented steel deck were: Densdeck Prime, Soprema Elastcol primer, Soprema Sopralene base sheet, Tremco Butyl tape, Radius Track pre-curved studs attached with varying height angle clips, Roxul Rockboard semi rigid insulation, and Kalzip Aluminum Panel standing seam.

“The segmented metal roof deck created variations ranging from 2 to 16 inches in the support heights for the track,” said Brett Moore of Gage Metal Cladding Ltd., the roofing contractor. The team looked to the sub-system to overcome the height differences created by the flat deck sections opposite the doubly curving roof.

Once contracted by Gage Metal Cladding, Radius Track executed a surface analysis of the finished skin compared to a 3-D scan of the segmented roof deck. Using that data, the Radius Track team generated a height differential “heat map” to identify height ranges. The analytical process provided information to color-code stand-off clips based on height. The installation team used color-coordinated layout drawings to match the color-coded clips to achieve the necessary height to connect to the pre-curved studs. This process set the geometry of the roof surface and provided the precise fastening surface for the Kalzip standing seam metal roof.

The collaboration between the sub-system and standing seam providers benefitted the roof installation process. The pre-fabricated light-gauge metal sub-system enabled the roofing contractor to focus on other scope of work items while the sub-system was designed, engineered and fabricated. Additionally, coordination of the sub-system and roofing panel 3-D models provided geometric fabrication precision and decreased risk. The insulation, airspace and high albedo metal panel roofing combined to deliver the geometry of the design intent and met Cool Roof requirements of the Toronto Green Standard.

Vaughan Metropolitan Centre Station

Traveling further north to the last station of the extension, Vaughan Metropolitan Centre station rises from the ground in a torus shape with thirty-nine skylights penetrating the shell. Here, the roof is topped with a zinc double lock standing seam metal roof system by Rheinzink. The entire assembly is built up from the structural steel deck with Densdeck Prime, Soprema Elastcol primer, Soprema Sopralene base sheet, Tremco Butyl tape, Radius Track pre-curved hat channel, track and stud connected by varying height stand-off clips, Dow Styrofoam rigid insulation, plywood sheathing, Soprema Shield, Enkamat thermal break, Rheinzink Zinc Panel double lock standing seam, and SnoFence snow retention system by S-5.

Like York University station, this roof installation included onsite unitization of pre-curved track and stud sections. Bothwell-Accurate pre-assembled sections of track and stud and lifted them into place while accommodating the skylights. A layer of plywood sheathed covered the pre-curved sub-system and was covered by another membrane. Between this membrane layer and the zinc cladding, a 3-D matt (Enkamat) was required to facilitate air movement, mitigate heat buildup, and evacuate moisture. Each layer of the inverted roof membrane assembly was carefully specified to deliver a durable finished product that honored the design intent and met the high performance cool roof criteria.

“There were many opportunities where things could have gone sideways,” said Alfredo Falcone of Adamson Associates, “we invested significant effort to ensure these projects followed the design intent and were built to the details.” Because the pre-curved sub-system was CNC fabricated using data extracted from the 3-D model it removed field cutting operations and decreased site debris. It set the geometry for the standing seam metal roof and provided a transition from the segmented deck to the doubly curved torus shell finished skin. Each layer of the assembly is an integral part of the success of this roof—by contributing as a barrier, protector, geometric determinate, mitigator or second barrier.

Metal Roofs Deliver Vision & Performance

These three transit stations highlight complex roof geometry as a key design feature. Each project leveraged expert collaboration, advanced processes and the capability of metal sub-framing and finished skin panels to successfully honor the design vision with Cool Roof performance. Trevor McGrath of Bothwell-Accurate commented, “Each of these stations gives back to every person passing through them in a way they may not be aware of, and provides a positive impact through the natural light, beautifully designed spaces and well-planned wayfinding.”