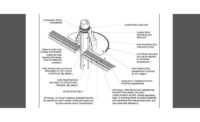

Roofing Detail: Gravel-Stop Flashing Joint Cover Plate

The profile of specific components, their configuration or sequencing, can vary with the roof system, climatic differences, and regional or area practices. Dimensions as shown are recommended minimums and are intended to be approximate to allow for reasonable tolerances due to field conditions.

Fasteners to attach edge flashing may be nails or screws, as may be recommended by the single-ply roofing membrane manufacturer. Consult specific membrane manufacturer for additional information. Four-inch minimum horizontal flanges are recommended.

Raised perimeter edges that can be roofed, base flashed, and counterflashed with perimeter coping or fascia cap metal are recommended in lieu of perimeter gravel-stop flashing. For examples of preferred raised perimeter details, see Details TP-4 and TP-7.

Raised perimeter edges that can be roofed, base flashed, and counterflashed with perimeter coping or fascia cap metal are recommended in lieu of perimeter gravel-stop flashing. For examples of preferred raised perimeter details, see Details TP-4 and TP-7.

For sunny, hot, and/or high altitude projects located in winter-time heating climates, WSRCA suggests that thermoplastic single-ply roof membranes and flashing ply(s) be white, or another light color, to provide a reflective surface minimizing heat gain and thermal aging.

Continuous cleats are recommended when flashing face dimension exceeds 3 inches and in areas deemed high-wind zone as categorized by local building code. Note that ES-1 guidelines have been adopted by the International Building Code.

Certain components as depicted in these details may not be provided by the roofing contractor.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!