What Do Model Energy Codes Mean for Continuous Insulation?

Recent improvements to model energy codes are boosting advances in the use of insulation for commercial and residential building envelopes. These changes are helping to offset energy costs, and improve the durability and resiliency of buildings. As a result, the methods and materials design professionals specify for thermal management in building projects are also changing.

In 2012, the International Code Council (ICC) published an updated International Energy Conservation Code (IECC) that called for a 30 percent increase over the 2006 code in building energy savings, the single largest efficiency increase in the history of the model energy code. Along with upgrading commercial roof insulation to current R-value code requirements, the 2012 IECC highlights continuous insulation (CI) systems as an effective design to increase thermal efficiency.

Continuous Insulation in Walls

In the ASHRAE 90.1 standard, Energy Standard for Buildings Except Low-rise Residential Buildings, CI is defined as:

"Insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior, exterior, or is integral to any opaque surface of the building envelope."

While this insulation approach is not new—it is quite common in low-slope roofing assemblies—its use on both residential and commercial building walls is changing the way builders and design professionals look at the building envelope. As cost and carbon footprint become more of a factor, model energy codes are emphasizing higher-performing wall assemblies, including those using CI. Like any construction material, insulation used in CI applications must be properly specified to ensure its intended performance and appropriate use.

Materials: Function and Versatility

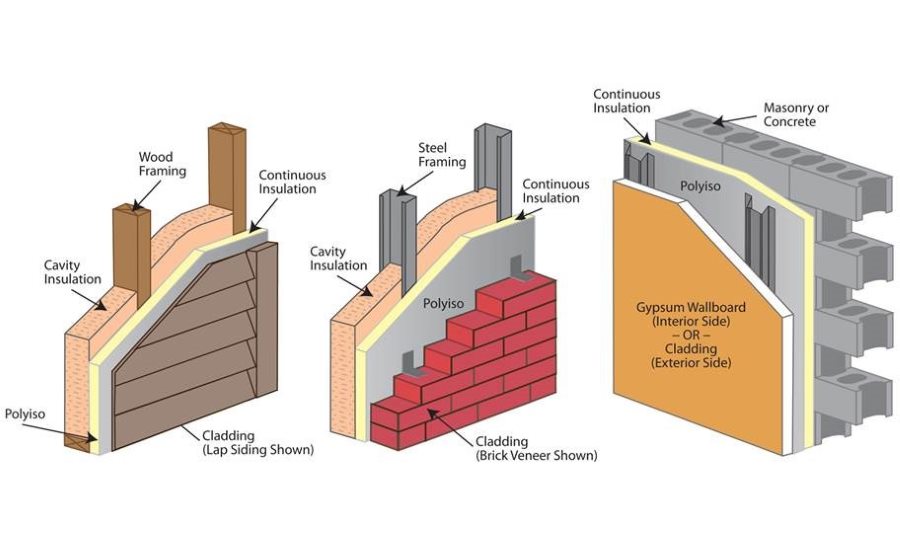

As the illustration shows, CI can be used with various residential and commercial wall structural systems and cladding materials like:

- Cement board

- Portland cement stucco

- Wood lap

- Brick veneer

- Stone

- Vinyl siding

In these applications, the primary function of CI is to improve energy performance and provide a cost-effective compliance option for more rigorous building energy code requirements. The benefits of CI extend beyond energy savings. Properly qualified and installed ci products can also serve as air- and water-resistant barriers. When laminated to structural materials, certain ci products can even improve the structural integrity of walls.

A variety of insulation materials can be relied upon to create continuous wall insulation, including:

- Polyisocyanurate (polyiso) foam

- Expanded polystyrene (EPS)

- Extruded polystyrene (XPS)

Each product type has different thermal performance properties and other physical properties that will influence a builder or design professional’s selection. Polyiso foam insulation has been relied upon for years as the go-to solution for energy-efficient low-slope commercial roofs, providing a ci solution for over 70 percent of commercials roofs. The many benefits of polyiso that have made the product a trusted solution for roofs can translate to residential and commercial walls.

Polyiso offers a high R-value per inch that allows designers to meet thermal envelope requirements with less material. The product’s light-weight boards make installation easier and certain polyiso products can be used as air and water-resistant barriers. These performance benefits can help lower material and labor costs for many projects.

Modern Energy and Building Code Requirements

CI is one of the most thermally efficient ways of complying with modern energy codes and mitigates heat loss due that commonly results from thermal bridging.

The performance of CI extends beyond energy savings. Testing has shown that CI systems can enchased the wind pressure resistance of wall assemblies when compared to assemblies that use only traditional materials. Many CI products can also be used as a water-resistive barrier behind cladding, offering water protection and thermal performance in one product. Design professionals also have the option to apply separate vapor barriers to walls with CI.

During installation, direct attachment of cladding through the CI system or furring placed over and attached through the CI can minimize thermal bridging from cladding connections. Properly matching the R-value of insulation to different climates and using adequate vapor retardants can prevent condensation by keeping walls above the dew point and allow seasonal drying capability.

Construction Detailing

Clear and detailed instructions for using continuous insulation (ci) in walls and roofs are critical to their successful use. Construction details to consider include:

- Envelope component attachments;

- Integration of flashing and water-resistant barriers;

- Integration of furring (if used) around wall penetrations and flashing;

- Attachment of cladding to wall framing through ci or to furring;

- Details for cladding attachments through ci at inside and outside corners; and

- Installation detailing per NFPA 285 tested assembly when required.

Continuous insulation is a high-performance building solution that can deliver multiple benefits to almost any residential or commercial project. It provides long-term thermal performance for the building while protecting against air infiltration and moisture, saves money on energy costs, and can improve the indoor conditions and comfort for building occupants.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!