The new Beckwith Animal Hospital was never about only being a state-of-the art veterinary facility. The objective to develop a state-of-the-art green facility was also among the top priorities for the ambitious undertaking. From the project’s inception, Dr. Michael O’Brien envisioned an environmentally responsible structure that was also interesting, innovative and would last long into the future. For Beckwith Animal Hospital, environmental responsibility was prioritized every step of the way, from the construction process to future use.

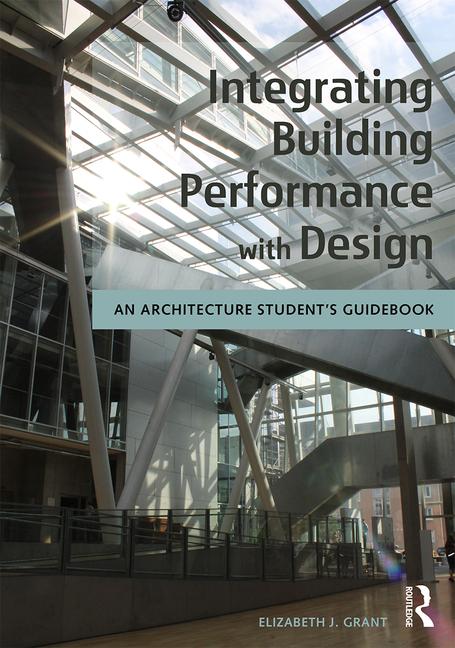

The Modesto, Calif. based project was designed to showcase the successful selection and integration of active and passive energy systems as well as efficient site use, with a visually appealing design capable of turning heads, complemented by numerous user-friendly innovations. For project’s architect firm Pires, Lipomi + Navarro, with a specialty area in medical facilities, the net result was more than just a design they’re proud to showcase. They also became recipient of the 2013 Sierra Valley Design Excellence Award.

LEED principals were key drivers for the project. By conceiving and building the project with LEED certification in mind, the company was better able to prioritize energy performance solutions. Selections of materials, systems and processes where not only selected on a nice-to-have or anticipated optimization basis, but according to how they would bring the project into line for the desired LEED credits.

Since the roof system’s performance is a key factor for energy efficiency and sustainability in any commercial structure, as well as a significant contributor to a building’s exterior appearance and durability, the facility designers put careful planning toward both the look, and the function of the building’s cover.

A metal roof appearance on the Beckwith Animal Hospital enhances the stone facades and carefully designed landscapes, while also providing a sleek modern aspect to the facility’s appearance. The roof materials selected, KingZip Insulated Standing Seam Metal Roof Panels in the 6-inch thick Copper Penny color design, offer polyiso insulation performance, clad in stunning exterior beauty and protection. Approximately 14,000 square-feet of material was installed on the roof, producing a classic appearance with modern appeal.

The project really consisted of two buildings—a 14,000-square-foot small animal building, and a large animal building of about 3,000 square-feet. The building’s exterior has a round silo type structure where the elevator is located. The building was designed to be earth-friendly throughout its entire life cycle. According to Tom Cosentino of Western Valley Development, the general contractor for Beckwith Veterinary Hospital, this is one of the most unique and eco-friendly projects he has ever worked on.

Use of the single section insulated roof panels provided the opportunity to expand the building envelope performance via use of a similar system on the exterior walls. Insulated panels were installed on over 7,000 square-feet of the existing wall. The Dakota Bronze color of the wall panels allowed the building’s wall tones to look solid and sophisticated but remain subtle while the more striking copper look of the roof stands out to the passerby’s attention.

The project includes integrated systems, which become economies of scale for the facility, while providing practical advantages. There is an underground cistern beneath the parking lot used to gather storm water. It holds up to 300,000 gallons, which can be used for landscape irrigation, and cooling air conditioning coils. The surrounding landscape also incorporates low water consuming elements.

For Beckwith, there was not only desire for a green facility but a green construction process, with minimum disruption of physical surroundings as well as efficient work and integration processes. The panels became another important economy of scale during the installation process, and promise to provide continued benefits throughout the performance lifecycle.

Both the roof panels and the metal wall panels combine energy efficiency with aesthetics and improved speed of build. Each product incorporates a dense, polyisocyanurate foam insulation core, with a stunning, design-specific exterior and interior face. The exterior face of the wall panels contains 24-gauge steel and is attached to the polyiso core in a continuous line process. A Granitstone acrylic aggregate stucco finish is factory applied, so when the panels arrive on site they can be installed in a single pass, increasing build speed, reducing installation costs, and helping logistics.

The insulated standing seam roof panels follow a similar process. The Beckwith project called for a 6-inch polyiso core clad in the standing seam Copper Penny finished steel exterior, with a steel underside. The roof surface looks clean because there are no through fasteners. The standing seam joint is mechanically zipped into place, so the fit is tight, and doesn’t permit airflow.

From a performance standpoint, both the roof and wall panels provide superior air tightness and help reduce thermal bridging, causing the building’s heating and cooling systems to be specified smaller and achieve better performance. The R-value is approximately R-70 in both the walls and ceiling. The building’s exposures are positioned so that PV panels, installed on top of the roof panels help reduce the amount of energy the facility requires off the grid, and allows it to provide energy at optimum times.

Not only is the new Beckwith Animal Hospital facility beautiful and efficient, it’s practical and employee-friendly, helping create a sophisticated and agreeable work environment employees are proud of. Motion equipped sensors help create lighting efficiency. The tobacco free property includes a full kitchen for employees, showers, a daycare, and a gym. The project also incorporates recycled materials whenever possible. A roof garden above the main entrance contributes to aesthetics. An actual redwood tree trunk in the lobby enhances redwood ceilings in the lobby and conference room.

Due to the many innovations and their corresponding approvals with the county, as well as other municipal considerations, the process took nearly three years from start to finish. The facility was constructed to achieve at least a Silver level LEED certification, which it proudly displays, due to the careful and innovative planning of Dr. O’Brien and the ability of Pires, Lipomi + Navarro to implement the owner’s vision using Kingspan insulated metal panels.