A Collaborative Approach to Temporary Earth Retention Systems for Foundations

Selecting a Sheet Pile System With Waterproofing Issues in Mind

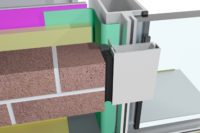

FIGURE 1: Pre-applied waterproofing typically is affixed onto plywood sheathing, which is permanently attached to the inside face of the vertical sheet pile system.

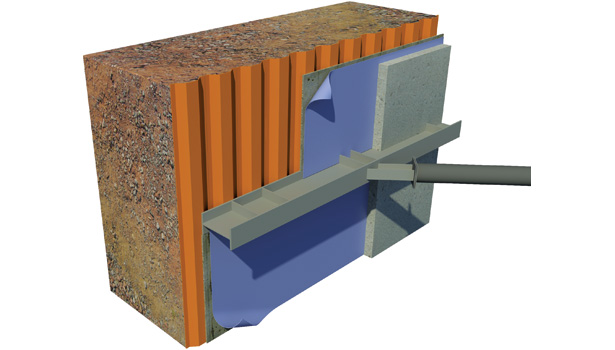

Figure 2: Sheet piles with tie backs are commonly used for earth retention on tight jobsites with high lateral pressures. Tie rods installed through the sheet piles and into the retained soil provide anchorage for the excavation.

Grout tubes are installed as a permanent assembly within the foundation wall. Photos courtesy of Simpson, Gumpertz & Heger.

Leaking is evident around cross-site bracing after torch cutting and parging.

Tie backs are installed within the bellies of the sheet piles, providing an unimpeded surface for the plywood substrate and the waterproofing.

Provide 3-5 feet of overlap at sequential levels of concrete placement to ensure a proper membrane lap.

Braced formwork is shown here.

Form ties are affixed to welded ties on the sheet piles which must be sealed at the waterproofing level before the concrete is placed. This condition provides a substantial risk of water leakage.

Below-grade waterproofing and temporary earth retention systems should be coordinated and designed in tandem to maximize continuity of the waterproofing system. We discovered that some designers and contractors do not consistently consider the impact that the selected sheet pile system can have on the continuity of the selected waterproofing system. Designers and contractors must understand the limitations of waterproofing systems in order to minimize damaging these systems, avoid leakage where possible, and plan for potential leakage mitigation with minimal disruption to interior occupation. This article will focus specifically on sheet pile retention systems and their impact on the waterproofing.

There are many ways to retain earth in congested urban construction, typically known as property line construction. Below-grade waterproofing implications abound and depend on the type of retention system that may be proposed by the geotechnical/structural engineer. A consultant versed in all aspects of below-grade waterproofing systems must participate in the discussion when the design team selects and develops the temporary earth retention system. Each system has positive and negative implications for detailing the continuity of the blind side, property line waterproofing.

Property line construction in the northeastern United States often relies on one of three main types of sheet pile excavation systems: cantilevered sheet piles, sheet piles with cross-site bracing, and sheet piles with tie backs (i.e., soil or rock anchors). For each of these systems, we will describe the blind side waterproofing considerations and limitations.

Various products are marketed as blind side or positive side waterproofing for property line foundations. This discussion will focus on the pre-applied sheet membrane system.

Pre-applied waterproofing typically is affixed onto plywood sheathing which is permanently attached to the inside face of the vertical sheet pile system (Figure 1). Formwork for the foundation wall is installed against the inside face of the waterproofing. When the concrete is placed against the form work, it integrally bonds the waterproofing to the outside (positive side) of the cast foundation wall. The continuity of the positive side waterproofing is critical in avoiding costly moisture mitigation procedures after construction.

Temporary Earth Retention Approaches

Cantilevered sheet piles: A cantilevered sheet pile system retains earth via a series of interlocking vertical steel sheets embedded into firm soil at the base. The soil pressure acting against the embedded portion of the sheeting resists the soil pressure acting on the exposed sheeting height. Because this system relies exclusively on the strength and stiffness of the cantilevering steel sheets, it is only practical for relatively shallow excavations — typically exposed heights less than 16 feet — with low earth pressures. Where excavations are deeper, or where tight control of lateral movements under earth pressure is important, a system incorporating braces or tie-back anchors (as described below) is more appropriate. However, in circumstances that permit it, a cantilevered sheet pile retention system can be appealing in its simplicity and in its notable absence of obstacles to the waterproofing.

Sheet piles incorporating horizontal waler beams and cross-site bracing: Sheet piles with cross-site bracing is one type of system that can be designed to resist high loads from earth retention, water retention and construction surcharge pressures while maintaining good control of lateral movement. In this system, steel beam walers welded to the inside face of the steel sheet piles connect to bracing elements that span between walls, across the building site, internally bracing the sheet piles. Once the permanent foundation walls have been placed and have reached an adequate strength, the cross site bracing is removed, typically via torch cutting. This type of bracing works well for smaller, relatively open building footprints, but it tends not to be practical on very large sites with long distances between opposing foundation walls or on sites with heavily congested below-grade spaces.

There are two approaches to walers in a cross-braced excavation system. The first approach that we will discuss involves leaving the walers permanently within the concrete foundation walls. The second approach that we will discuss involves removing the walers as the below-grade concrete floors are constructed. Each approach has implications for the design and installation sequence of the waterproofing system.

Walers remaining within the foundation walls: Walers and cross site bracing are obstacles to the continuous installation of the plywood sheathing onto the sheet piles and, ultimately, to the continuity of the waterproofing membrane. As described above, the waler is welded directly to the sheet piles (Figure 1). Thus, discontinuity of the plywood and waterproofing creates a vulnerable area in the system. The edge of the waterproofing has to be located at the steel waler itself, which creates a transient bond due to the inherent rusting of steel in service. At these areas, consider installing preformed grout injection tubes along the extent of the discontinuity. The grout tubes should be a permanent assembly within the wall construction and should be affixed to the steel to prevent dislodgement during concrete placement (Photo 1). The grout tubes should be installed such that they penetrate the full depth of the foundation wall with an injection port visible on the finished interior surface when the forms are removed. This will allow unimpeded access to an injected hydrophobic, water stop, liquid grout compound at the first sign of water penetration into the structure. Grout formulation depends on the type of leakage observed (i.e., dampness as opposed to running water).

There is always the possibility with this type of waterproofing design that post-applied injection ports will have to be drilled into the foundation, and multiple rounds of grout injection should be expected.

While the walers remain permanently within the foundation walls, the cross-site bracing is removed after the concrete walls reach strength. Typically, cross-site bracing is removed by torch cutting the steel to the plane of the interior finished foundation wall. The exposed cut-off steel is parged with cement-based mortar to blend into the surrounding concrete foundation walls. The torch operators must be meticulous, or heat blankets must be installed integral with the construction, as the heat from the cutting process can transfer through the steel and burn the waterproofing and render it ineffective (Photo 2).

Walers removed during construction: Foundation wall construction typically progresses in full floor-to-floor wall placements, resulting in a cold joint in the wall at each floor level. In this approach, the walers are removed when the concrete floor below has reached sufficient strength to laterally brace the wall. Typically, the waler is installed at a minimum height above the floor. As noted above, the waterproofing is interrupted at the horizontal walers and is integrally bonded to the foundation wall. Since torch cutting of the waler can result in damage to the waterproofing, sufficient space must be provided between the lap of the waterproofing membrane and the waler to facilitate installing protection and making effective repairs before the next level of foundation wall is formed and placed. Towards this end, the design team should consider locating the walers a minimum of 3-4 feet above the top of the floor slab.

Sheet piles with tie-back anchors: Sheet piles and tie-back anchors comprise another commonly used earth retention system on tight jobsites with high lateral pressures (Figure 2). In this system, tie rods installed through the sheet piles and into the retained soil provide anchorage for the excavation. The depth of the excavation and the pressure of the soil and any water behind the sheet piles, as well as the anticipated construction surcharge loading, determine the required vertical and horizontal spacing of the anchors. A tie-back system has the benefit of keeping the building footprint clear during construction, but it requires ownership of the site beyond the extent of the sheet piles, since the tie rods must extend as far behind the sheet piles as needed to encounter stiff clay or rock for anchorage. On sites where adequate anchorage material does not exist or is located far away from the building, tie backs may not be a practical system. Also, this system is not practical if the streets beyond the extents of the excavation are heavily congested with buried utilities, such as storm water and sewer systems, unless the project team is committed to precisely locating and coordinating with these buried utilities.

At multi-level excavations with high earth, water, and construction surcharge pressures, tie rods are anchored to horizontal walers on the inside face of the sheet piles. The walers, which may be formed from a rolled beam section or from a section of corrugated sheet pile, distribute the tie rod reactions over the interlocking sheet piles so that the steel sheet does not experience a large concentrated load at its connection to the tie rod. Where these walers are included in the earth retention system, they pose an obstruction to the waterproofing, similar to that described in the section above. Sheet pile systems with smaller tie rod forces — due to shallower excavations, lower retention pressures, more frequent spacing of the tie rods, or any combination thereof — may allow the tie rods to anchor directly into the sheet pile, without the use of a waler. Where the system employs this type of anchorage, local stiffener sections, such as channels or plates, installed between the webs of the sheet piles can reduce the local stresses from the tie rod reactions on the steel sheets.

Sheet piles with tie backs are a viable system for continuity of the waterproofing layer, though the plywood sheathing installed as the substrate for the waterproofing contains holes that have to be meticulously detailed by the sheathing installer. There are special accessory tie-back cover products that integrate at the waterproofing membrane level; these can add cost to the installation and create more seams which are detrimental to the continuity of the waterproofing. To improve conditions for the installation of continuous plywood and waterproofing, consider installing the tie-back anchors in the bellies of the sheet piles and stiffening the sheets locally. Designing and installing the anchors in this manner permits uninterrupted installation of the plywood across the inner face of the sheet pile system (Photo 3), which then acts as a suitably continuous surface to which to affix the positive side waterproofing (Figure 2). Coordination is required to ensure that a minimum of 3 to 5 feet of waterproofing membrane is exposed above the level of the concrete placement for an appropriate lap of the sequential membrane, especially at floor levels (Photo 4).

Other Considerations

Most municipalities require that the final elevation of the perimeter sheet pile be located at least 5 feet below the finished grade. The sheet piles typically are installed to an above-grade height during construction, which means they must be cut down before finished landscaping can begin. As described earlier, the preferred method of removing elements of the sheet pile system is with the use of torches. The heat from the torch can ignite the plywood substrate and burn the waterproofing. If this happens, it is impossible to repair the damaged waterproofing, which is behind the remaining sheet pile. Custom detailing, accounting for the location of future torch cutting operations, is required in order to provide appropriate means of arresting heat transfer through the system. Fire retardant plywood and woven heat blankets (installed prior to the waterproofing installation) were implemented successfully on a recent project to protect the integrity of the waterproofing system.

Always consider using internally braced formwork for the concrete placement operation (Photo 5). Form work relying on form ties for resistance of concrete pressure during placement requires ties across the foundation wall rebar cage in grid patterns of approximately 2 feet on center. The ties typically connect to the steel sheet piles (through the pre-applied waterproofing). Each penetration in the waterproofing must be sealed, which poses a significant risk for water leakage through the many penetrations that will be created (Photo 6). The basis of good waterproofing design is to maintain a solid and continuous membrane. Every hole that must be patched in order to accommodate a form tie increases the likelihood of failure of the waterproofing system.

Conclusions

In selecting a temporary earth-retention system, the team should consider a number of factors including the required excavation depth, the anticipated earth, water, and construction surcharge pressures, ownership of the land beyond the building foundation walls, the quality of soil or rock surrounding the site, the building plan geometry, the anticipated congestion level in the footprint during construction, and the ease with which waterproofing can be installed around the various proposed systems. Many building sites are candidates for more than one type of excavation system, and the relative costs of the various systems are dependent on the unique site characteristics.

The project team should discuss all of the above considerations with a consultant versed in all aspects of below-grade waterproofing systems at the earliest possible point in the project. The owner should participate in the discussion and should clearly state his or her tolerance for potential leakage. When the project constraints demand the selection of a system that introduces waterproofing complications, the design team must understand the issues and potential waterproofing risks associated with selection and implementation of a specific retention system and ensure that the owner is aware of them as well. In this way, appropriate safe guards can be included within the system, and potential leakage can be anticipated, with potential remediation included in the budget.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!