IBC 2012

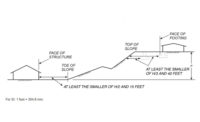

Section 1805.2

Dampproofing

Where hydrostatic pressure will not occur as determined by Section 1803.5.4, floors and walls for other than wood foundation systems shall be dampproofed in accordance with this section. Wood foundation systems shall be constructed in accordance with AF&PA PWF.

Dampproofing

Code Interpretation

This section implies that dampproofing is required for all below-grade floors and walls where hydrostatic pressure will not occur. ASTM defines dampproofing as the treatment of a surface or structure to block the passage of water in the absence of hydrostatic pressure. Fundamentally, it only has the ability to resist vapor migration. If soil analysis concludes that there is no hydrostatic pressure or if the water table is more than six (6) inches below the lowest floor, then dampproofing may be considered.

Dampproofing is always applied at the exterior (wet) face of the wall. The most common dampproofing material for walls is a bituminous coating, either solvent-based (cutback asphalt) or emulsion, which is brushed, sprayed, roller-coated or troweled on the substrate. Dampproofing systems may also include membranes. The general difference between waterproofing systems and dampproofing systems is that dampproofing membranes maximize at 10-mil film thickness while waterproofing membranes exceed this thickness.

The section also implies that wood foundations shall be constructed in accordance with Permanent Wood Foundation Design Specification (ANSI/AF&PA PWF - 2007).