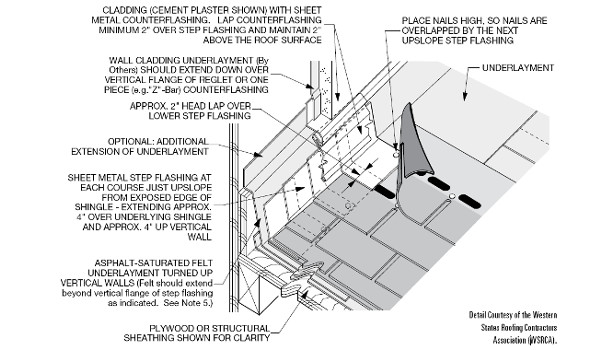

Proper flashing is a critical component of all roof systems. On steep-slope shingle applications, flashings at vertical intersections are completed with metal step flashings. Step flashings should be fabricated from a non-corrosive metal such as minimum 24-gauge galvanized metal or 16-ounce copper.

The step flashing is applied over underlayment that is applied over the vertical substrate and under the shingle. The step flashing should extend a minimum of 4 inches up the vertical surface, and a minimum of four inches onto the substrate (under the shingle). The step flashing is fastened to only the deck — with appropriate fasteners — with one fastener per flashing. Fastening of step flashing is not recommended at vertical surface to allow for movement. The fasteners should be placed on the high (up-slope) portion of the horizontal metal piece so that fasteners are covered over by the overlapping step flashing. Step flashing should overlap a minimum of 2 inches, and application should begin at the eave and rise up to the ridge.

Some applications require cladding or sheet metal counter flashing for aesthetics. In these cases, the covering material should only cover the top 2 inches of the step flashing.