Window on the Future

New thinking on fenestration products means a window doesn’t have to represent a gaping hole in the thermal envelope.

|

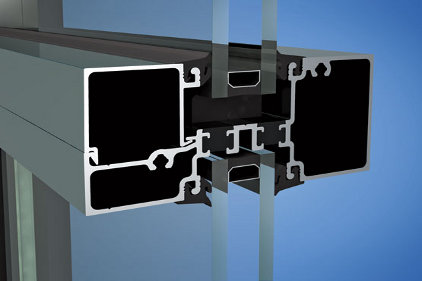

| Advanced framing design incorporating a double polyurethane thermal barrier to significantly reduce heat transfer. |

Energy codes and standards play a significant role in the United States construction market by influencing the design of commercial buildings. Once a code or standard is adopted by lawmakers, it becomes a legal requirement that protects our society from substandard building practices and ensures a minimum level of energy efficiency is achieved. Architects frequently turn to the International Energy Conservation Code and the American Society of Heating, Refrigerating and Air-Conditioning Engineers 90.1 standard to assist in creating project specifications. Complying with these codes and standards is a requirement to obtain building permits. However, many times the performance that results from these baseline codes is not enough to meet the needs of the building’s owners.

Current baseline codes do not meet the needs of green building practices. A recent trend has been to design buildings that achieve levels of energy efficiency above standard code. The trend has spawned the creation of alternative “green” codes and standards such as the ASHRAE 189.1 and the International Green Conservation Code (IgCC), which are more stringent and require higher levels of thermal performance. While these alternative standards are available to be specified on green building projects, the baseline codes still influence the majority of commercial construction projects. Therefore, an effort to make baseline codes more stringent has recently gained momentum in order to reduce the energy demands of commercial buildings in the United States.

To support increased energy efficiency in America’s built environment and help advance energy codes, the U.S. Department of Energy established a Building Energy Codes Program. This effort has influenced and driven recent changes in energy codes. For example, in 2004, the IECC code was modified to require all operable windows to have a minimum U factor of 0.35. This was beyond the ability of readily available commercial products to satisfy and this version of the code was not widely adopted by jurisdictions. While later baseline codes relaxed the requirements for commercial products, the industry faced a call to action to design new products for future code cycles. Recent trends in baseline codes and standards have continued to require higher performance from fenestration products. The most recent version of the IECC took a big step in raising the minimum level of energy efficiency, as it mandates prescriptive performance requirements that are close to current green codes and standards (see Image 1). With DOE’s long-term vision of achieving net-zero commercial construction by 2025, it is very clear to the commercial fenestration industry that new designs are required to meet the market’s future thermal performance needs.

Fenestration: A Key Component of the Building and Thermal Envelope

A key component of the building envelope, fenestration provides natural light into the occupied space and allows occupants to connect with nature. Studies prove that increased natural light and increased vision area have a positive impact on mental health and productivity. So, maximizing the amount of fenestration on the building envelope is a key strategy. The concern is that fenestration has typically been a weak point in the thermal envelope. Many may recall when monolithic glazing and non-thermally-broken aluminum framing systems were widely used in commercial construction. The thermal attribute of these products was nearly equivalent to leaving gaping holes in the sides of buildings. Energy could easily pass through these products, placing a significant demand on HVAC equipment keeping the occupied space conditioned. Even if the equipment was robust enough to maintain a desired temperature, the areas adjacent to the windows remained undesirable because of the product’s interior surface temperatures, inability to control condensation and sensation of drafts.

|

| Image 1: Advanced fenestration products establish a new baseline of performance for greater energy efficiency. |

Due to its versatility and durability, aluminum is the preferred material for fenestration products used in commercial construction today. Aluminum systems can be easily manufactured to meet the architect’s aesthetic designs with affordable custom extrusions. In addition to delivering a high level of structural integrity at a low weight ratio, aluminum can be produced with superior finishes for durable, long lasting performance. It is also a good conductor of energy—an undesirable characteristic in framing materials. For this reason, thermal barrier technologies have been used for decades to minimize heat loss by interrupting energy flow.

The primary products used today across America incorporate thermal barriers and accept standard one-inch insulating glass. Polyamide strips and polyurethane cavities are commonly found in standard aluminum framing materials to help resist energy flow. These products have the ability to meet current codes with standard glazing. They also allow for more efficiency by incorporating high performance glazing to meet today’s green codes. However, they are not robust enough to meet upcoming baseline codes and future green building requirements.

Establishing a New Baseline for Fenestration Products

Recently-introduced fenestration products significantly improve the thermal performance of the whole product and establish a new baseline of performance (see Image 2). Simulation tools such as Therm and Windows 5.0—developed with funding from DOE—allow manufacturers to simulate the thermal performance of various designs prior to production. Designers now have the capability to not only analyze the placement of thermal barriers, but also analyze the extrusion design to minimize heat flow through the profile assemblies. This process helps close the thermal performance gap between the framing system and the glazing system and yields an overall product with superior thermal performance. The result is a new generation of framing systems that have greatly improved thermal performance attributes and provide a more comfortable interior environment. Surface temperatures of the frame are raised and improve human comfort when in close proximity to the fenestration systems. This higher surface temperature also improves condensation resistance, which is an equally important performance metric in commercial construction.

These advanced products incorporate multiple thermal barriers (see opening image). What’s more, they are capable of achieving current green building requirements and future baseline codes with readily available glazing infills. This concept is important because it lowers the overall price point in achieving this level of performance. Also, one can assume future green codes will also specify performance more stringent than the current code. By integrating high performance glazing with the advanced framing—and ultimately achieving the new baseline codes with standard glazing—architects can maintain their ability to achieve performance more stringent than code. So, how can architects ensure the correct product combination is specified to meet their requirements?

Make Sure Products Meet Code

|

| Image 2: Prescriptive requirements of commercial fenestration products. |

Along with the advancement of framing systems, the fenestration industry has developed tools to communicate the energy performance of whole products. The American Architectural Manufacturer’s Association released AAMA 507, a standard practice for determining the thermal performance of fenestration systems. By utilizing the same simulation standards defined by the National Fenestration Rating Council, AAMA 507 allows architects to quickly understand the whole product’s performance. It provides a fast and accurate analysis of how different insulating glass systems will perform within the framing system. AAMA 507 thermal certificates are readily available from fenestration manufacturers to demonstrate compliance to specifications and codes.

NFRC, which is known for its residential window certification program, recently released a program to independently certify the thermal performance of commercial fenestration products, the Component Modeling Approach program. Similar to the concepts deployed in the AAMA 507 standard, the CMA program allows whole product energy performance ratings for commercial projects. The concept behind component modeling is performance data from the three primary components—frame, glass and spacer assemblies. These three systems are combined on a project-by-project basis to generate the overall product performance rating.

Create Healthier, More Comfortable and Energy-Efficient Buildings

Fenestration manufacturers are answering the market’s call for increased energy efficiency by launching advanced framing systems as standard products that meet and exceed future energy codes. Architects now have the ability to select advanced designs throughout all categories incorporated into the building envelope—entrance doors, storefronts, curtain walls, balcony doors, operable windows and sun control devices. By continuing to invest in research and new products, the commercial fenestration industry is in a strong position to meet future challenges and help reduce the energy demands of U.S. commercial buildings—ultimately creating healthier, more comfortable and energy-efficient buildings.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!