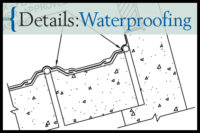

Waterproofing Details: Typical Tie-In Details

One of the most critical details on remedial applications is the tie-in detail between the existing waterproofing application and the new waterproofing application. Failures at this point often occur due to incompatibility of the waterproofing membranes. It is essential that the designer determine whether the materials can be adhered or if a control joint and/or expansion joint is required. For instance, most of the waterproofing materials provided on the market today are not compatible with coal-tar, which was the most prevalent waterproofing material used up through the early 1990s.

If the materials are compatible, then apply the new membrane flashing material over the existing membrane. Application is completed using a compatible bitumen or lap sealant and by applying the new flashing a minimum of 6 to 9 inches over the horizontal substrate and over the existing material by a minimum of 6 to 9 inches.

Some manufacturers require that a 1/2-inch by 1/2–inch reglet be cut into the deck substrate at the termination point of the new membrane (approximately 6 to 9 inches from the existing membrane) to serve as a water cutoff point between the two systems.

|

|

Detail courtesy of American Hydrotech, Inc. |

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!